Most rear-wheel drive and all-wheel drive vehicles have gearboxes that turn and change torque. The basis of such gearboxes are bevel pairs - read all about these mechanisms, their types, design and operation, as well as their correct choice and replacement, in the article.

What is a conical pair?

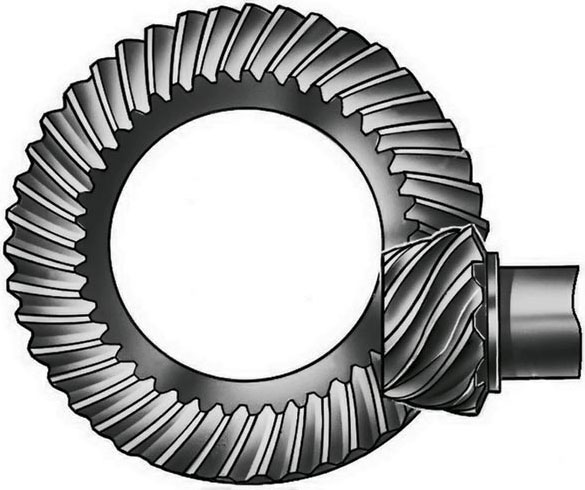

A bevel pair is a type of gear transmission of vehicles and other equipment, formed by two bevel gears, the axes of which are located at an angle (usually straight) to each other.

In the transmissions of vehicles, tractors and machines, as well as in various equipment, there is often a need to change the direction of torque flow. For example, in rear-wheel drive vehicles, the torque transmitted by the propeller shaft is perpendicular to the axle axis, and this flow must be rotated 90 degrees to drive the wheels. In MTZ wheeled tractors with a front drive axle, the direction of the torque flow must be turned 90 degrees three times, since the axles of the wheels are located below the axis of the post beam. And in many units, machinery and equipment, the torque flow must be rotated at different angles several times. In all these cases, a special gear train based on two bevel gears is used - a bevel pair.

A conical pair has two main functions:

- Rotation of the torque flow at a particular angle (most often 90 degrees);

- Changing the amount of torque.

The first problem is solved by the design of the gears of the bevel pair, the axes of which are located at an angle to each other. And the second problem is solved by using gears with a different number of teeth, as a result of which a gear train with a particular gear ratio is formed.

Bevel pairs play a key role in the operation of many transmission mechanisms and other systems, if one or both gears wear out or break, the entire pair must be replaced. But before buying a new conical pair, you need to understand the design of this mechanism, its existing types, characteristics and features of work.

Types and design of conical pairs

Any bevel pair consists of two gears having a bevel shape of the initial surfaces, and intersecting shaft axes. That is, the gears of the pair have a bevel shape, and they are located at right or different angles to each other.

Bevel pairs differ in the shape of the teeth and the arrangement of the gears relative to each other.

It should be noted that the gears of the bevel pair, depending on the purpose, have their own name:

● The drive is just a cogwheel;

● The slave is a gear.

According to the shape of the teeth, conical pairs are:

● With straight teeth;

● With curved teeth;

● With circular teeth;

● With tangential (oblique) teeth.

Gears with straight teeth are the simplest in design - they are cut parallel to the axis of the wheel. Circular teeth are more complex, they are cut around the circumference of a particular diameter. Tangential (or oblique) teeth are similar to straight teeth, however, they are deflected from the gear axis. The most complex are curvilinear teeth, the handicap of which is set by various formulas (functions). Such a variety in the shape of the teeth of bevel gears is explained by differences in the load capacity of gears and their noise. Gears with straight teeth withstand the least loads, they are also the most noisy. Oblique tooth gears are less noisy and run more smoothly. And the greatest loads can withstand gears with curved and circular teeth, they are also the least noisy.

According to the relative position of the gears, the pairs are divided into two large groups:

● Ordinary, with the coincident vertices of the initial surfaces of the gears (that is, if you imagine the gears in the form of cones, then their vertices will converge at one point);

● Hypoid, with displaced vertices of the initial surfaces of the gears.

Conical pair with circular tooth Hypoid conical pair with curved tooth

In the first case, the axes of the gears are located in one plane, in the second - in one of the planes, the axes are offset. Hypoid gears can only be composed of bevel gears with oblique or curved teeth, they have a high load capacity and operate almost silently.

Bevel gears can be made at the same time with the shaft or separately from it. Usually, the shaft has small-diameter gears, the large gears of the drive axle gearboxes have a large internal hole for mounting on the differential housing. Gears are made of special grades of steel using various technologies - turning and milling, knurling, stamping followed by knurling, etc. Conical pairs require constant lubrication for their operation, and special brands of greases are used in hypoid gears.

Performance and standardization of bevel gears

Of the main characteristics of bevel gears should be highlighted:

● Gear ratio - calculated from the ratio of the number of teeth of the gear and the wheel (usually lies in the range from 1.0 to 6.3, although it may differ in a big way);

● Average normal and outer circumferential modules;

● Geometric dimensions of gears.

There are also other parameters of bevel gears, but during operation or for repairing gearboxes or other mechanisms, they are practically not used.

It should be noted that in Russia the characteristics and design features of bevel gears are standardized, the gears and the mechanisms themselves are manufactured in accordance with GOST 19325-73 (common to all gears based on bevel gears), 19624-74 (spur gears), 19326-73 (gears with circular teeth), GOST 1758-81 and others.

Applicability of conical pairs in vehicles

Bevel gears are most often used in gearboxes of transmissions of vehicles for various purposes:

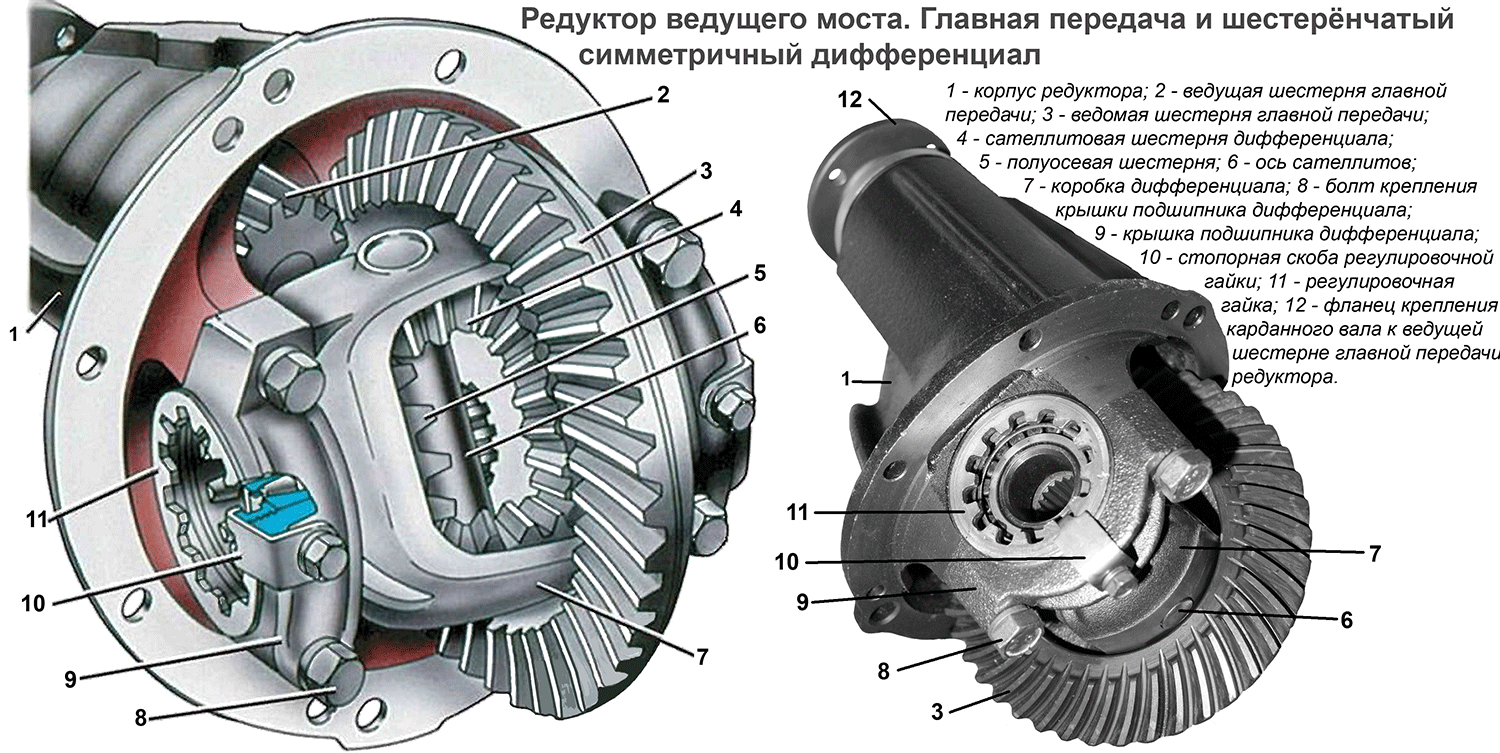

The bevel pair is one of the bases of the drive axle gearbox

● As the main gear in the gearboxes of the drive axles of rear-wheel drive and all-wheel drive vehicles. Typically, such a transmission is made in the form of a pair of gears of different sizes, one of which (slave) is mounted directly on the differential housing. The single-drive gear is made together with the shaft, the double gear is made with a shaft and another gear (bevel or cylindrical);

● As upper and lower gearboxes of the driving front axles of wheeled tractors. In the upper gearboxes, both gears can have the same number of teeth and dimensions, they are made at the same time with their shafts. In the lower gearboxes, the driven gear is made of large diameter and has a special design for connection with the wheel;

● In various units of transmission and other systems. Conical pairs may have different designs, but in general they correspond to what is said above.

Thus, a car can have from one (on a vehicle with one drive axle) to three (in all-wheel drive three-axle vehicles) or more (in multi-axle vehicles with all-wheel drive) bevel pairs, and in tractors with a front drive axle there are four bevel pairs, at least one more such mechanism can be used in the transmission of the tractor to turn the torque to the power take-off shaft.

How to choose and replace a conical pair correctly

During the operation of the vehicle, the conical pair is subjected to significant loads - it is through it that all the torque from the engine is supplied to the drive axle, and it is also subjected to vibrations, shocks and shocks due to interaction with other parts. As a result, over time, the teeth of the gears wear out at the points of contact, chips and hardening may appear in them, and in some cases the teeth are completely chipped. All this is manifested by the deterioration of the mechanism and increased noise. If a malfunction is suspected, the mechanism must be disassembled and checked, in the event of a gear breakdown, the bevel pair must be replaced. It does not make sense to change only one of the gears, since in this case the mechanism will soon become a source of problems again.

A conical pair should be taken for replacement, which in design, size and characteristics corresponds to the previously installed mechanism. If necessary, you can choose a mechanism with a different gear ratio, which will improve the performance of the vehicle. However, such a replacement should be done with caution and only with full confidence that it is possible and justified - this can be reported by the manufacturer himself or specialists.

Replacement of the bevel gear must be carried out in accordance with the instructions for repairing the car or tractor. Usually, this work requires significant intervention in the drive axle and gearbox - to replace the gears, it is necessary to almost completely disassemble the axle and its individual mechanisms. In some cases, bearings and sealing elements will have to be replaced - they should be purchased in advance. When installing gears and assembling the gearbox, it is necessary to use the manufacturer's recommended lubricants. And after the repair is completed, a short break-in of the gearbox is necessary.

With the correct selection and replacement of the conical pair, the repaired transmission mechanism will work reliably, performing its functions in all modes.

Post time: Jul-13-2023