Many modern vehicles use air suspension with adjustable parameters. The basis of the suspension is an air spring - read all about these elements, their types, design features and functioning, as well as the correct choice and replacement of these parts, in the article.

What is an air spring?

Air spring (air spring, air cushion, air spring) - an elastic element of the air suspension of vehicles; pneumatic cylinder with the ability to change the volume and rigidity, located between the wheel axle and the frame / body of the car.

The suspension of wheeled vehicles is built on elements of three main types - elastic, guide and damping. In various types of suspensions, springs and springs can act as an elastic element, various kinds of levers can act as a guide (and in spring suspension - the same springs), shock absorbers can act as a damping element. In modern air suspensions of trucks and cars, these parts are also present, but the role of elastic elements in them is performed by special air cylinders - air springs.

The air spring has several functions:

● Transmission of moments from the road surface to the frame / body of the car;

● Changing the stiffness of the suspension in accordance with the load and current road conditions;

● Distribution and equalization of the load on the wheel axles and individual wheels of the car with uneven loading;

● Ensuring the stability of the vehicle when driving on slopes, road irregularities and turning;

● Improving the comfort of the vehicle when driving on roads with different surfaces.

That is, the air spring plays the same role in the wheel suspension system as a conventional spring or spring, but at the same time allows you to change the stiffness of the suspension and adjust its characteristics depending on road conditions, loading, etc. But before purchasing a new air spring, you should understand the existing types of these parts, their design and principle of operation.

Types, design and principle of operation of air springs

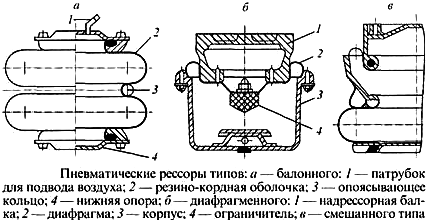

Three types of air springs are currently in use:

● Cylinder;

● Diaphragm;

● Mixed type (combined).

Air springs of various types have their own design features and differ in the principle of operation.

Types and design of the air springs

Cylinder air springs

These are the simplest devices in design, which are widely used on various vehicles. Structurally, such an air spring consists of a rubber cylinder (a multilayer rubber-cord shell, similar in design to rubber hoses, tires, etc.), sandwiched between the upper and lower steel supports. In one support (usually in the top) there are pipes for supplying and bleeding air.

According to the design of the cylinder, these devices are divided into several types:

● Barrel;

● Bellows;

● Corrugated.

In barrel-shaped air springs, the cylinder is made in the form of a cylinder with straight or rounded (in the form of half a torus) walls, this is the easiest option. In bellows devices, the cylinder is divided into two, three or more sections, between which the girdle rings are located. In corrugated springs, the cylinder has corrugation along the entire length or only on its part, it may also have girdle rings and auxiliary elements.

Air springs of balloon (bellows) type

The cylinder-type air spring works simply: when compressed air is supplied, the pressure in the cylinder rises, and it is slightly stretched in length, which ensures the lifting of the vehicle or, at high load, keeping the level of the frame / body at a given level. At the same time, the stiffness of the suspension also increases. When air is vented from the cylinder, the pressure decreases, under the influence of the load, the cylinder is compressed - this leads to a decrease in the level of the frame / body and a decrease in the stiffness of the suspension.

Often, air springs of this type are simply called air springs. These parts can be used both in the form of independent elastic suspension parts, and as part of additional elements - springs (large-diameter coiled springs are located outside the cylinder), hydraulic shock absorbers (such struts are used on cars, SUVs and other relatively light equipment), etc.

Diaphragm air springs

Today, there are two main varieties of this type of air spring:

● Diaphragm;

● Diaphragm sleeve type

The diaphragm air spring consists of a lower body-base and an upper support, between which there is a rubber-cord diaphragm. The dimensions of the parts are selected in such a way that part of the upper support with a diaphragm can enter the inside of the base body, on which the work of this type of air springs is based. When compressed air is supplied to the housing, the upper support is extruded and lifts the entire frame/body of the vehicle. At the same time, the stiffness of the suspension increases, and when driving on uneven road surfaces, the upper support oscillates in the vertical plane, partially damping shock and vibration.

Air springs of balloon (bellows) type

The sleeve-type diaphragm air spring has a similar design, but in it the diaphragm is replaced by a rubber sleeve of increased length and diameter, inside which the base body is located. This design can significantly change its length, which allows you to change the height and stiffness of the suspension over a wide range. Air springs of this design are widely used in the suspensions of trucks, they are usually used as independent parts without additional elements.

Combined air springs

In such parts, the components of diaphragm and balloon air springs are combined. Usually, the cylinder is located in the lower part, the diaphragm is in the upper part, this solution provides good damping and allows you to adjust the characteristics of the suspension within a wide range. Air springs of this type are of limited use on cars, more often they can be found on railway transport and in various special machines.

diaphragm air spring

The place of air springs in the suspension of the vehicle

The air suspension is built on the basis of air springs located on each axle on the side of the wheels - in the same place where conventional longitudinal springs and struts are installed. At the same time, depending on the type of vehicle and the operating loads, a different number of air springs of one type or another can be located on one axle.

In passenger cars, separate air springs are rarely used - most often these are struts in which hydraulic shock absorbers are combined with conventional, bellows or corrugated air springs. On one axis there are two such racks, they replace the usual racks with springs.

In trucks, single air springs of hose and bellows types are more often used. At the same time, two or four air springs can be installed on one axis. In the latter case, sleeve springs are used as the main elastic elements, providing a change in the height and stiffness of the suspension, and bellows springs are used as auxiliary ones, which act as dampers and serve to change the stiffness of the suspension within certain limits.

Air springs are part of the overall air suspension. Compressed air is supplied to these parts through pipelines from receivers (air cylinders) through valves and valves, air springs and the entire suspension are controlled from the cab / interior of the car using special buttons and switches.

How to choose, replace and maintain air springs

Air springs of all types during the operation of the vehicle are subjected to significant loads, which leads to their intensive wear and often turns into breakdowns. Most often we have to deal with damage to the rubber-cord shells, as a result of which the cylinder loses its tightness. Breakdowns of the air springs are manifested by the roll of the vehicle when parked with the engine turned off and the inability to fully adjust the stiffness of the suspension. The defective part must be checked and replaced.

A spring of the same type that was installed earlier is used for replacement - the new and old parts must have the same installation dimensions and performance characteristics. In most cars, you will have to buy two air springs at once, as it is recommended to change both parts on the same axle, even if the second is quite serviceable. Replacement is carried out in accordance with the instructions for the vehicle, usually this work does not require significant intervention in the suspension and can be carried out quite quickly. During the subsequent operation of the car, air springs must be regularly inspected, washed and checked for tightness. When performing the necessary maintenance, the air springs will work reliably, ensuring the high-quality functioning of the entire suspension.

Post time: Jul-13-2023