On trailers and semi-trailers of foreign production, the components of the chassis from the German concern BPW are widely used. To mount the wheels on the chassis, a specialized fastener is used - BPW studs. Read all about this fastener, its existing types, parameters and applicability in the material.

Purpose and functions of BPW wheel studs

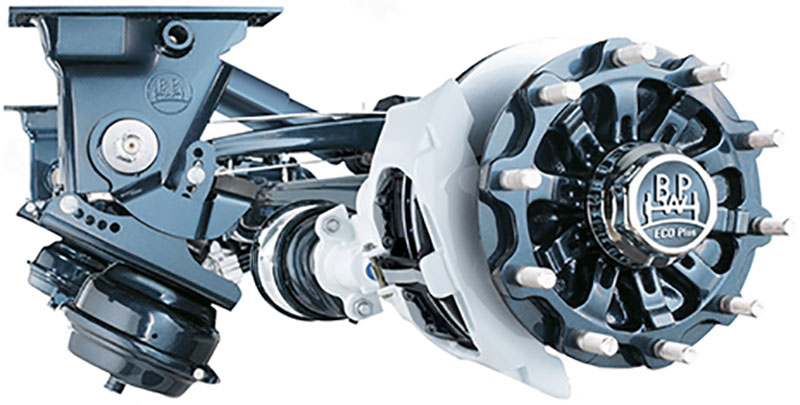

The BPW wheel stud (hub stud) is a specialized fastener in the form of one- and double-sided studs designed for mounting wheels on axles manufactured by BPW, used on trailers and semi-trailers.

The German concern BPW specializes in the production of elements of the chassis of trailers and semi-trailers - under this brand, axles, trolleys, monitoring and control systems, and other components of the chassis are produced. The company pays great attention not only to the main components, but also to hardware, therefore, under the BPW brand, a fasteners that are critical for the operation of the chassis are also produced - wheel studs.

BPW wheel studs perform one function: installation of a brake drum/disc and a wheel disk(s) assembly with the tire(s) on the hub. This fastener during the operation of the trailer is subjected to considerable static and dynamic mechanical loads and the effects of negative factors that cause corrosion, therefore they require periodic replacement. To successfully replace bpW wheel studs, it is necessary to understand their nomenclature, applicability and design features.

Types and nomenclature of BPW wheel studs

Three main types of wheel studs are available for the BPW chassis:

● Scorers;

● Hammered under the pin;

● Standard (double-sided).

The hammered stud is made in the form of a threaded rod with a head that acts as a stop. Unlike the bolt, the head of the hammered stud is smooth, there are two types:

● Semicircular - the round head is partially cut off.

● Flat - the stud has a T-shape.

Due to the complex shape of the head, the stud is fixed in the corresponding recess of the hub, which prevents its cranking. Additionally, the stud is fixed in the hole due to the grooved thickening under the head. When installed, such a stud is hammered all the way into the corresponding hole in the hub, for which it got its name.

Single-sided wheel studs BPW

Double-sided BPW wheel stud

BPW wheel stud included with nut

Hammered studs under the pin usually have a T-shape (flat head), in a certain place transverse drilling is performed - a pin is installed in this hole, which prevents spontaneous coagulation of the nut.

Hammered studs are produced with thread M22x1.5, total length 80, 89 and 97 mm, only for single-slope tires.

The double-sided stud has a standard device: it is a steel rod, at both ends of which a thread is cut; in the middle part of the stud, a thrust burt is made to ensure the correct position of the fastener relative to the hub and other parts.

Double-sided studs are available in the following types:

● Thread M20x1,5 on both sides, length 101 mm;

● Thread M22x1,5 on one side and M22x2 on the other side, length 84, 100, 114 mm;

● Thread M22x2 on both sides, length 111 mm.

On double-sided studs, the length of the thread on the side of the hub and the wheel is different, usually these parameters are indicated in the specialized spare parts catalog BPW.

In this case, the studs are divided into two groups by purpose:

● Under the single-sided tire - for fastening the wheel with one tire;

● Under the gable tire - for fastening wheels with two tires.

Short studs are designed for a single-slope tire, long ones for a gable one.

Hub studs are available in different configurations:

● Only stud without nuts and washers;

● Stud with a regular nut and a grover-type washer;

● Stud with nut with press washer (nut with "skirt");

● Stud with nut, cone washer and grover type washer.

Double-sided studs can have the same nuts and washers on both sides, but most often a regular nut with a grover and a nut with a press washer are used in the kit, less often the stud can be equipped with an additional cone washer.

BPW wheel studs are made of structural steels and are subjected to corrosion protection - galvanizing or oxidizing (fasteners of this type have a black color). Hardware is produced both by BPW itself and by third-party manufacturers, which greatly expands the choice of parts for repair.

How to choose and install BPW studs correctly

Wheel studs of axles are one of the most loaded parts of the chassis of trailers and semi-trailers, these loads and the impact of negative environmental factors lead to intensive wear of the studs, and in some cases - to their deformation and destruction (fracture). Faulty studs are subject to early replacement, since the reliability of the entire chassis and the safety of trailer operation depend on their reliability.

For replacement, it is necessary to use the same studs that were installed on the trailer / semi-trailer earlier, fasteners of a different length or with a different thread simply will not stand in place and will not hold the parts together. Replacement should be carried out in strict accordance with the instructions for repairing the bridge or BPW trolley. Usually this work requires removing the wheel and brake drum / disc, to dismantle the studs requires the application of great physical effort, but for high-quality and fast performance of work it is recommended to use a stud puller. To remove broken double-sided studs, special devices are required - extractors. Before installing new studs, it is necessary to clean their seats and hub, and when installing fasteners, you need not to forget about washers and auxiliary parts. Tightening the nuts on the studs must be performed with the force recommended by the instructions, if the tightening is too strong, the parts will work with excessive stresses and may get damaged, with a weak tightening, the nuts can spontaneously turn away, which will have negative consequences.

If the BPW wheel studs are picked up and replaced correctly, the undercarriage of the trailer or semi-trailer will work reliably in all conditions.

Post time: May-06-2023