In the wheel brakes of most modern cars there is a component that provides fixation and protection of parts - the brake shield. All about the brake shield, its main functions and design, as well as the maintenance and repair of this part, you can learn from the article.

What is a brake shield?

Brake shield (shield, protective cover, protective screen) - a part of the wheel brakes of wheeled vehicles; A metal part in the form of a round or semicircular shield that holds some parts of the brake mechanism and protects them from pollution, mechanical damage and negative environmental influences.

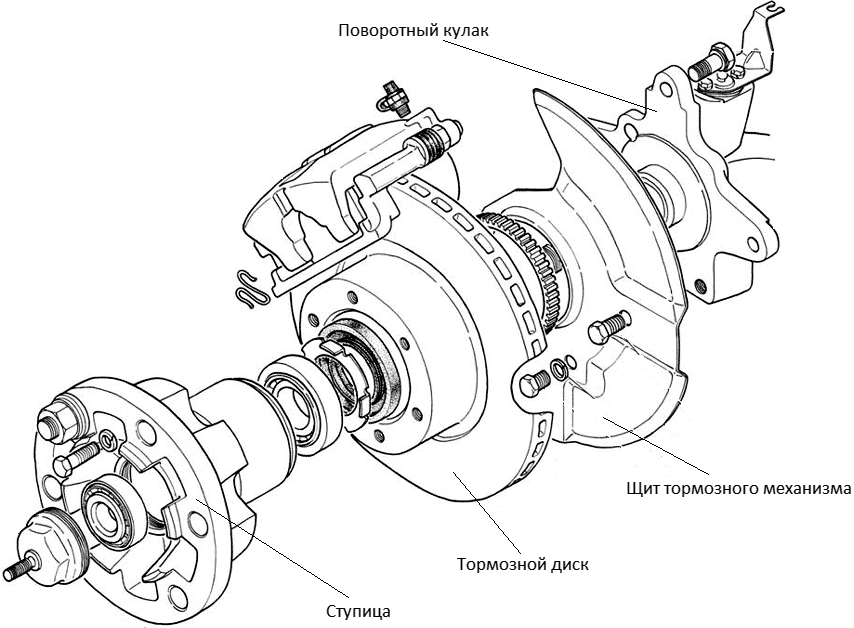

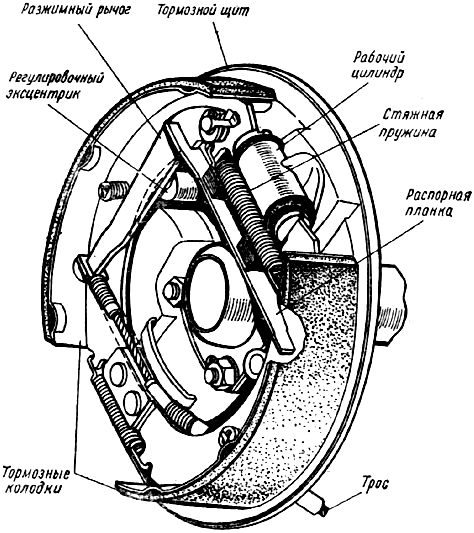

All modern wheeled vehicles are equipped with friction-type brakes located directly on the axle of the wheels. Traditionally, wheel brakes have two parts: movable, connected to the wheel hub, and fixed, associated with the steering knuckle (on the front steered wheels), suspension parts or axle beam flange (on rear and unsteered wheels). The movable part of the mechanism includes a brake drum or disc rigidly connected to the hub and wheel disc. In the fixed part there are brake pads and their drive (cylinders, caliper with cylinders in disc brakes), and a number of auxiliary parts (parking brake drive, various kinds of sensors, return elements and others). Fixed parts are located on a special element - the shield (or casing) of the brake.

The shield is located on the inside of the wheel brake mechanism, it is attached directly to the steering knuckle, bridge beam flange or suspension parts, several functions are assigned to it:

● The function of the power element is to hold the fixed parts of the wheel mechanism, ensuring their correct position in all modes of operation of the brakes;

● The function of the body element is to protect the parts of the brake mechanism from the ingress of large mechanical impurities and foreign objects, as well as their protection from mechanical damage due to contact with other parts of the car structure and foreign objects;

● Service functions - providing access to the main adjustment elements of the mechanism for performing maintenance and visual inspection of the brakes.

The brake shield is not a critical part for the operation of the brakes, however, if this component breaks down or is missing, the brakes are subject to intense wear and can fail in a short time. Therefore, in case of any problems with the shield, it must be replaced, and in order to make the correct repair, it is necessary to understand the design and features of these parts.

The device of the disc brake mechanism and the place of the shield in it The design of the drum brake mechanism and the place of the shield in it

Types and design of brake shields

On cars and various wheeled vehicles, brake shields that are fundamentally identical in design are used: this is a stamped steel part in the form of a circle or semicircle, in which various holes, niches and auxiliary elements are made for the installation of brake components. Usually, the shield is covered with black paint, which protects the part from corrosion. Various details can be located on the shield:

● The central hole for the wheel hub or axle shaft;

● Mounting holes - for mounting the shield to the fixed part of the suspension;

● Viewing windows - for access to the parts of the brake mechanism without dismantling the wheel and the shield itself;

● Holes for fastening parts of the brake mechanism;

● Hinges and brackets for fixing springs and other parts of the mechanism;

● Pressed bushings for inserting cables, installing axes of levers, sensors and other parts;

● Platforms and stops for centering and correct orientation of parts.

At the same time, there are two types of brake shields in terms of applicability: for disc and drum brakes. They have a different design, which also depends on the location - on the front steered wheels, on the rear drive wheels or on the wheels of the rear driven axle.

Structurally, the shields of the front and rear wheels of cars with disc brakes are the simplest. In fact, it is just a steel stamped casing, mounted on a steering knuckle (under the hub) or on fixed suspension elements, and taking on only protective functions. As a rule, only the central hole, a number of mounting holes and a figured cutting for the part of the caliper protruding from the inside of the wheel are made in this part.

More complex are the shields of all wheels with drum brakes. The entire mechanism is located on such casings - the brake cylinder (or cylinders), pads, pad drive parts, springs, parking brake drive elements, adjusting elements and others. The shield has a central hole and mounting holes, with the help of which the entire assembly is mounted on the flange of the drive axle beam or suspension elements. This type of part has more serious requirements for strength and rigidity, as it plays an important role in the operation of the entire brake mechanism. Therefore, it is made of stronger and thicker metal, often has stiffeners (including an annular board around the perimeter of the shield) and auxiliary reinforcement elements.

In conclusion, it should be noted that brake shields are solid and composite. In the first case, it is a single stamped part, in the second - a prefabricated part of two parts (half rings). Most often, components are used on trucks, they facilitate the installation, maintenance and repair of brakes, and in case of damage, it is enough to replace only one half, which reduces costs.

Issues of maintenance, selection and replacement of brake shields

The brake shield does not require special maintenance during the operation of the vehicle - it must be inspected at each maintenance of the brakes, and, if necessary, cleaned of contaminants. If the shield is damaged or deformed (especially the drum brake shield), it is recommended to replace it. For repairs, it is necessary to use a part of the same type and catalog number that was installed earlier. Moreover, it should be borne in mind that the shields are not only front and rear, but also right and left.

The replacement of the part should be carried out in accordance with the instructions for the repair and maintenance of this particular vehicle. Usually, this work boils down to the following:

1.Lift the car with a jack (after braking it and ensuring immobility);

2.Remove the wheel;

3.Dismantle the brake drum or disc with the caliper (this may require a number of auxiliary operations - breaking the drum from the seat by screwing in the screws, and others);

4.Dismantle the wheel hub (in disc brakes, the hub is often removed along with the shield);

5.Dismantle the brake shield with all the parts installed on it (this may require a special key, and access to fasteners is often opened only through special holes in the hub).

Brake shield with installed brake parts

If a car with disc brakes is being repaired, then all work is reduced to a simple replacement of the casing. After that, the entire node is assembled in reverse order. If the work is carried out on a car with drum brakes, then after dismantling the shield, it is necessary to remove the brake parts from it, install them on a new shield, and then reassemble them. After repair, it is necessary to perform all operations to regulate the hub bearing (if provided), as well as to maintain and adjust the brake system of the car.

You can see that replacing the brake shield only seems simple - for this you have to almost completely disassemble the wheel and the mechanisms located in it. Therefore, it is necessary to choose the right part and perform repairs in compliance with all the recommendations of the automaker. If a mistake is made, then it will take a lot of time and effort to correct it. A reliable result can only be achieved with the right purchase of spare parts and a deliberate approach to repair work.

Post time: Jul-12-2023