Even a simple pneumatic system contains several connecting parts - fittings, or adapters for the compressor. Read about what a compressor adapter is, what types it is, why it is needed and how it works, as well as the correct selection of fittings for a particular system - read the article.

Purpose and functions of the compressor adapter

Compressor adapter is a common name for fittings used to make connections in mobile and stationary pneumatic systems.

Any pneumatic system, even consisting of a compressor, one hose and a tool, requires several connections: hoses to the compressor, hoses to each other, tools to hoses, etc. These connections must be sealed, so special fittings are used for their implementation, which is often called compressor adapters.

Compressor adapters are used to solve several problems:

● Hermetic connection of hoses with other components of the system;

● Creation of turns and branches of air routes;

● Ability to quickly connect and disconnect system components (using quick couplings);

● Temporary or permanent closure of certain sections of air routes;

● Some types of fittings - protection against air leaks from the receiver when the air lines and tools are disconnected.

Fittings are important elements that allow you to assemble reliable and easy-to-use pneumatic systems, and in the future change and scale them. The choice of adapters should be approached responsibly - information about the existing types of fittings, their design and characteristics will help here.

Design, classification and features of compressor adapters

There are two main groups of fittings used in pneumatic systems:

● Metal;

● Plastic.

Metal adapters are made of brass (both with and without nickel coating), stainless steel, ductile iron. This group of products is used to connect all types of hoses with a compressor and pneumatic tools.

Plastic adapters are made of various grades of high-strength plastics, these products are used to connect plastic hoses to each other.

There are several main types of adapters with different applicability:

Quick couplings ("quick releases");

Hose fittings;

● Thread-to-thread adapters;

● Fittings for various connections of air lines.

Each type of fittings has its own design features.

Plastic direct adapter for overhead

Quick couplings

These adapters are used to perform quick coupling of pneumatic system components, which allows you to quickly change the type of tool, attach various hoses to the compressor, etc. Such adapters are often called "quick releases", they are of three main types:

- With a ball closing mechanism (such as "rapid");

- Tsapkovogo type;

- With bayonet nut.

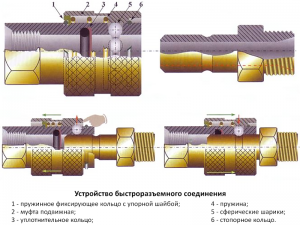

The most common connections are with a ball closing mechanism. Such a connection consists of two parts: a coupling ("mother") and a nipple ("father"), which fit into each other, providing a tight connection. On the "dad" there is a fitting of a special shape with a rim, in the "mother" there is a mechanism of balls arranged in a circle that jam and fix the fitting. Also on the "mother" there is a movable coupling, when displaced, the parts are separated. Often in the "mother" there is a check valve that opens when the "dad" is installed - the presence of a valve prevents air leakage when the connector is disconnected.

Tsapk-type joints also consist of two parts, each of which has two curly protrusions ("fangs") and two wedge-shaped platforms. When both parts are connected and rotated, the fangs engage with the platforms, which ensures reliable contact and sealing.

Connections with a bayonet nut also consist of two parts: "mom" with a split nut and "dad" with a counterpart of a certain handicap. When installing the "dad" in the "mom", the nut turns, which ensures jamming of parts and a reliable connection.

Quick coupling device with ball closing mechanism

Snap quick coupling

The quick-release parts on the reverse side can have different types of connections:

● Herringbone fitting under the hose;

● External thread;

● Internal thread.

There are quick couplings with various auxiliary parts: springs to prevent bends and breakage of the hose, clips for crimping the hose and others. Also, quick-detachers can be combined in two, three or more pieces with a common body with channels, such adapters provide connection to one line of several hoses or tools at once.

Hose fittings

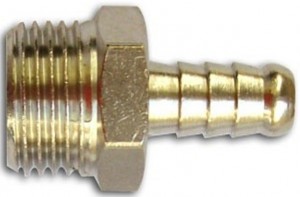

This group of parts is used to connect hoses with other components of the system - compressor, tool, other air lines. The fittings are made of metal, two parts are formed on them: the fitting for connecting to the hose, and the reverse for connecting to other fittings. The outer surface of the fitting part is ribbed ("herringbone"), which ensures its reliable connection with the inner surface of the hose. The reverse part may have an external or internal thread, a fitting of the same or a different diameter, a rapid fitting for quick release, etc. The hose is connected to the fitting using a steel clamp or a special cage.

Quick-release connection to the fitting

Thread-to-thread adapters and fittings for overhead lines

This is a large group of fittings that contains:

● Adapters from a thread of one diameter to a thread of another diameter;

● Adapters from internal to external (or vice versa);

● Corners (L-shaped fittings);

● Tees (Y-shaped, T-shaped), squares (X-shaped) - fittings with one entrance and two or three outputs for branching air lines;

● Collet plastic fittings;

● Threaded or fitting plugs.

Hose fitting with external thread

T-shaped adapter for air lines

Parts of the first three types are arranged simply: these are metal products, at the working ends of which external or internal threads are cut.

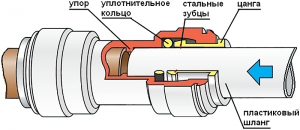

Collet fittings are more complicated: their body is a tube, inside of which there is a movable split sleeve (collet); When installing a plastic hose in a collet, it is clamped and fixes the hose. To connect such a connection, the collet is pressed into the body, its petals diverge and release the hose. There are plastic collet fittings for switching to metal threads.

Traffic jams are auxiliary elements that allow you to drown out the air line. Corks are made of metal, most often have a thread and a turnkey hexagon.

Design of collet type adapter for plastic hose

Characteristics of compressor adapters

Of the characteristics of fittings for pneumatic systems, three should be noted:

● The diameter of the hose fitting;

● Thread size and type;

● The range of pressures at which the adapter can be operated.

The most commonly used fittings are "herringbone" with a diameter of 6, 8, 10 and 12 mm, fittings with a diameter of 5, 9 and 13 mm are much less common.

The threads on the adapters are standard (pipe cylindrical) inch, 1/4, 3/8 and 1/2 inches. Often, in the designation, manufacturers also indicate the type of thread - external (M - male, "father") and internal (F - female, "mother"), these indications should not be confused with the indication of metric or some other thread.

As for the operating pressure, it is important for quick couplings. As a rule, most of these products can operate under pressure from tenths to 10-12 atmospheres, which is more than enough for any pneumatic system.

Issues of selection and operation of adapters for the compressor

When choosing compressor adapters, you should consider the type of system, the purpose of the fittings, the inner diameters of the hoses and the connecting dimensions of the fittings already in the system.

To make quick couplings in order to connect the hose to the compressor and / or pneumatic tools, it makes sense to give preference to devices with a ball locking mechanism - they are simple, reliable, provide a high degree of tightness, and if there is a valve, prevent air leakage from the receiver or other components of the pneumatic system. In this regard, bayonet and trunnion connections are less reliable, although they have an undeniable advantage - an extremely simple design and, as a result, high reliability and durability.

To connect the hoses, you should use herringbone fittings, when buying them, you also need to take care of the clamp. Clamps and clips are also needed in other connections with hoses, often these parts come complete with fittings, which removes the problem of finding and buying them.

If the hose is operated in conditions in which it often bends and can break, then an adapter with a spring will come to the rescue - it will prevent bends of the hose and extend its life.

If it is necessary to perform branching of air lines, then various tees and splitters will come to the rescue, including those with built-in quick releases. And to solve the problem of fittings of different diameters, threaded and fitting adapters of the appropriate types will come in handy.

Installation and operation of compressor adapters must be carried out in accordance with the instructions that come to the fittings and components of the pneumatic system - this will ensure reliable connections and safe operation of the system.

Post time: Jul-10-2023

Compressor adapter: reliable connections of pneumatic systems

Compressor adapter: reliable connections of pneumatic systems