In modern engine cooling systems, units are used to compensate for thermal expansion and fluid leaks - expansion tanks. Read all about expansion tanks, their purpose, design and features, as well as the correct choice and replacement of this part in the article.

What is an expansion tank?

Expansion tank - a unit of the liquid cooling system for internal combustion engines; A specially designed vessel designed to compensate for leaks and thermal expansion of the coolant circulating in the system.

Expansion tanks are also used in other systems of vehicles, tractors and special equipment: in power steering (power steering) and in hydraulic systems for various purposes. In general, in terms of purpose and design, these tanks are similar to the tanks of the cooling system, and their distinctive features are described below.

The expansion tank performs several functions:

● Compensation for the thermal expansion of the coolant when the engine heats up - excess fluid flows from the system into the tank, preventing pressure growth;

● Compensation for coolant leaks - a certain supply of liquid is always stored in the tank, which, if necessary, enters the system (after the release of liquid, the atmosphere during overheating, in the event of minor leaks, etc.);

● Monitoring the coolant level in the system (using the appropriate marks on the tank body and the built-in sensor).

The presence of a tank in the liquid cooling system is due to the characteristics and physical properties of the coolant - water or antifreeze. As the temperature rises, the liquid, in accordance with its coefficient of thermal expansion, increases in volume, which leads to an increase in pressure in the system. With an excessive increase in temperature, the liquid (especially water) can boil - in this case, excess pressure is discharged into the atmosphere through a steam valve built into the radiator plug. However, with the subsequent cooling of the engine, the liquid acquires a normal volume, and since part of it was lost during the release of steam, the pressure in the system drops - with an excessive decrease in pressure, the air valve built into the radiator plug opens, the pressure in the system is aligned with atmospheric. In this case, air enters the system, which can have a negative impact - air plugs form in the radiator tubes that prevent normal fluid circulation. So after bleeding steam, it is necessary to replenish the level of water or antifreeze.

Antifreezes of various types have a higher coefficient of thermal expansion compared to water, so the processes described above occur more intensively. To eliminate these negative effects, an expansion tank connected to the radiator is introduced into the cooling system. When the temperature rises, excess liquid is simply discharged into the tank, and when the engine cools, it returns to the system. This significantly increases the threshold for discharging steam into the atmosphere and increases the interval between replenishments of the liquid level in the system.

The expansion tank plays an important role in the operation of the cooling system and the entire power unit, so in case of any malfunction, it must be replaced. To choose the right tank and correctly perform repairs, you must first understand the existing types and features of these parts.

Design and features of expansion tanks

The expansion tanks used today have a fundamentally identical design, which is simple. This is a container with a volume of no more than 3 - 5 liters, the shape of which is optimized for placement in the engine compartment of the car. Currently, the most common are tanks made of translucent white plastic, but metal products are also on the market (as a rule, for old domestic cars VAZ, GAZ and some trucks). There are several elements in the tank:

● Filler neck, closed with a plug with steam and air valves;

● Fitting for connecting a hose from an engine cooling radiator;

● Optional - a fitting for connecting a hose from a thermostat;

● Optional - a fitting for connecting a hose from the radiator of the cabin heater;

● Optionally - a neck for installing a coolant level sensor.

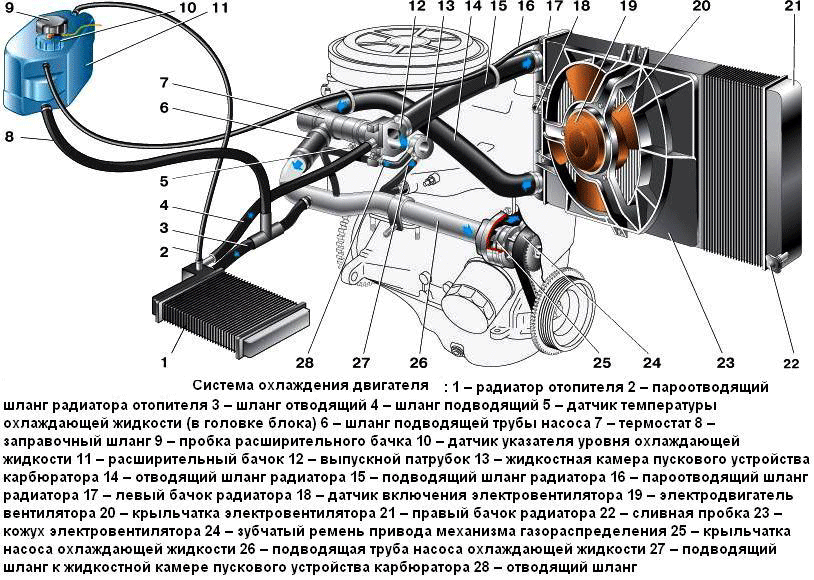

The engine cooling system and the place of the expansion tank in it

Thus, in any tank there must be a filler neck with a plug and a fitting for connecting a hose from the main radiator for cooling the power unit. This hose is called a steam exhaust hose, since hot coolant and steam are discharged from the radiator through it. With this configuration, the fitting is located at the lowest point of the tank. This is the simplest solution, but compensation for coolant leaks is carried out through the radiator, which in some cases reduces the efficiency of the cooling system.

In many tanks, a hose is additionally used to connect to the thermostat, in this case the steam exhaust hose is connected to the fitting in the upper part of the tank (on one of its side walls), the fitting for connecting to the heater radiator has the same position. And the hose going to the thermostat is removed from the fitting at the bottom of the tank. This design provides better filling of the cooling system with working fluid from the tank, in general, the system works more efficiently and reliably.

Almost all modern expansion tanks use a liquid level sensor built into a specially designed neck. Most often it is an alarm of the simplest design, which notifies of a critical decrease in the coolant level, but, unlike the fuel level sensor, does not inform about the current amount of liquid in the system. The sensor is connected to the corresponding indicator on the dashboard of the car.

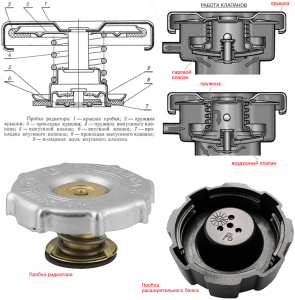

Expansion tank plug with separate valves

The plug of the expansion tank, like the plug of the main radiator, has built-in valves: steam (high pressure) to relieve pressure when the coolant is excessively heated, and air to equalize the pressure in the system when it cools. These are ordinary spring-loaded valves that are triggered when a certain pressure inside the tank is reached - when the pressure increases, the steam valve is squeezed out, when the pressure decreases, the air valve. The valves can be located separately or combined into a single structure.

Radiator and expansion tank plug with combined valves located on the same axis

The tank is installed in the engine compartment near the radiator, connecting to it and other components by means of rubber hoses of various cross-sections. The tank is slightly raised above the radiator (usually its midline coincides with the upper level of the radiator), which ensures the free flow of liquid (by gravity) from the tank to the radiator and / or to the thermostat housing. The tank and radiator form a system of communicating vessels, so the level of liquid in the tank can also be estimated by the level of liquid in the radiator. For control, a scale or separate marks with pointers "Min" and "Max" can be applied to the tank body.

Expansion tanks for power steering systems and hydraulics have a similar design, but they are made only of metal, as they operate under high pressure. Also in these parts there are no level sensors and marks, but the plug is necessarily equipped with valves to equalize the pressure in the system in various modes. The hoses are connected using special tips, sometimes with the help of threaded fittings.

Issues of proper selection and replacement of the expansion tank

During the operation of the vehicle, the expansion tank is exposed to high temperatures, significant pressure drops and corrosive environments (antifreeze, exhaust gases, fuel, oils, etc.) - all this can lead to damage to the tank and filler cap. The most common problems of plastic tanks are cracks in the body and ruptures due to excessive pressure growth. In any of these cases, the tank must be replaced, and repairs must be made as soon as possible.

Only the tank of the type and catalog number that was installed on the car by the manufacturer should be taken for replacement - this is the only way to guarantee the correct operation of the entire system. If the plug is also out of order (as usually indicated by a rupture of the tank due to a malfunction of the steam valve), then you need to buy it. If the old plug works fine, then it can be installed on a new tank. The old liquid level gauge, as a rule, is also placed on the new tank without any problems.

Replacement of the expansion tank must be carried out in accordance with the instructions for the repair of the vehicle. Usually, to perform this operation, you need to drain the antifreeze, disconnect all hoses from the old tank, dismantle the tank (it is held by a clamp, sometimes with additional screws) and install a new part in reverse order. At the same time, it may be necessary to replace old clamps, so you should immediately take care of their purchase. And if an old plug is installed, then it needs to be checked and, if necessary, cleaned.

After installation, it is necessary to fill in new antifreeze and close the plug, with the right choice, replacement and connection of a new tank, the entire system will immediately begin to work normally, ensuring effective cooling of the power unit.

Post time: Jul-17-2023