In automotive cooling systems with an electric fan drive, the fan is automatically turned on and off when the coolant temperature changes. The main role in the system is played by the fan turn on sensor - you can learn everything about this component from this article.

What is a fan switch-on sensor?

A fan switch-on sensor is an electronic or electromechanical device with a contact group (groups) that closes or opens an electrical circuit depending on the temperature. The sensor is included in the power supply circuit or control of the drive of the electric fan of the engine cooling system, it is a sensitive element that gives a signal to turn on or off the fan depending on the temperature of the coolant (coolant).

These sensors are only used in vehicles equipped with electrically driven radiator cooling fans. The engine crankshaft-driven fans are switched on and off by means of a viscous clutch or by other means that are not considered here.

Types of fan switch-on sensors

All fan sensors are divided into two groups according to the principle of operation:

•Electromechanical;

•Electronic.

In turn, electromechanical sensors are divided into two types:

• With a sensing element based on a working fluid with a high coefficient of expansion (wax);

• With a sensing element based on a bimetallic plate.

Due to the design features, electromechanical sensors can be connected directly to the fan power supply circuit (although more often the sensor is included in the fan relay circuit), and electronic sensors can only be connected to the fan drive control circuit.

Also, electromechanical sensors are divided into two types according to the number of contact groups:

• Single-speed - have one contact group, which closes in a certain temperature range;

• Two-speed - have two contact groups that close at different temperatures, which allows you to change the fan speed depending on the coolant temperature.

In this case, contact groups can be in one of two states: normally open and normally closed. In the first case, the fan turns on when the contacts are closed, in the second - when they open (additional control circuits can be used here).

Finally, the sensors differ in the on/off temperature of the fans. In domestic devices, intervals of 82–87, 87–92 and 94–99 ° C are provided, in foreign devices the temperature intervals lie approximately within the same boundaries, differing by one to two degrees.

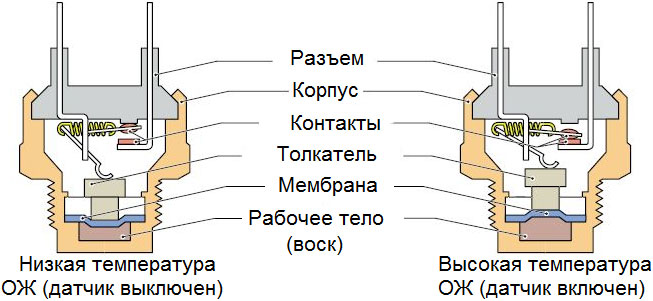

Design and principle of operation of an electromechanical sensor with wax

This is the most common type of fan sensors. The basis of the sensor is a container filled with petroleum wax (ceresite, consists mainly of paraffins) with an admixture of copper powder. The container with wax is closed with a flexible membrane on which the pusher is located, connected to the mechanism of the drive of the movable contact. The contact drive can be direct (using the same pusher) or indirect, using a lever and a spring (in this case, a more reliable closure and opening of the circuit is achieved). All parts are enclosed in a thick-walled metal case (this provides a more uniform heating of the working fluid) with a thread and an electrical connector.

The principle of operation of such a sensor is based on the effect of changing the volume of the working fluid when the temperature changes (it is also used in car thermostats). Wax, which plays the role of a working fluid in the sensor, has a large coefficient of thermal expansion, when heated, it expands and is displaced from the container. The expanding wax rests against the membrane and causes it to rise - that, in turn, moves the pusher and closes the contacts - the fan turns on. When the temperature drops, the membrane lowers and the contacts open - the fan turns off.

Two-speed sensors use, respectively, two membranes and two movable contacts, which are triggered at different temperature intervals.

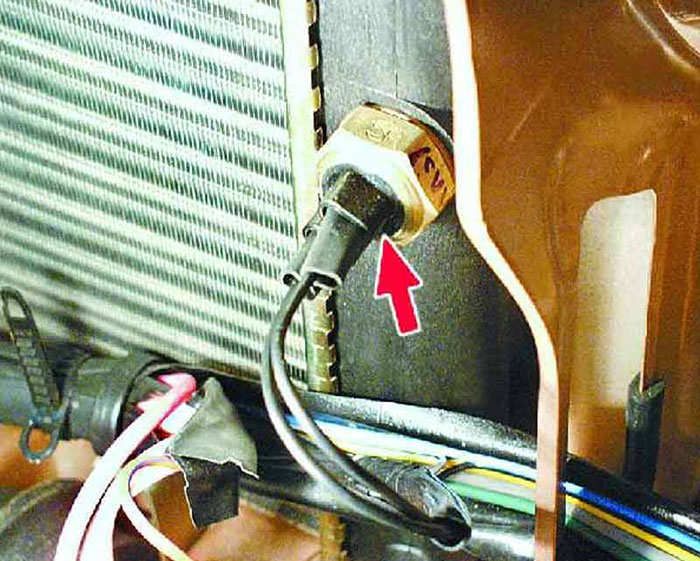

The sensor is mounted on the cooling radiator (through a sealing gasket), its working part is in direct contact with the coolant, from which the working fluid heats up. Usually, a car uses one fan sensor, but today you can also find solutions with two single-speed sensors set to different temperatures.

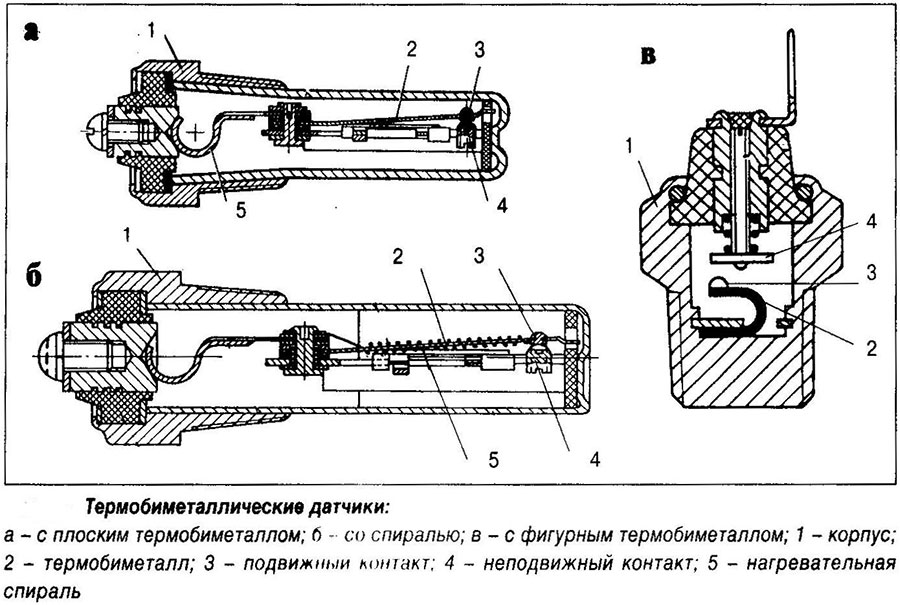

The design and principle of operation of the sensor with a bimetallic plate

There are many varieties of sensors of this type, but in general, their design is quite simple. The basis of the sensor is a bimetallic plate of one shape or another, on which the movable contact is located. There may also be auxiliary components in the sensor for more reliable contact closure. The plate is placed in a sealed metal case, which provides a thread and an electrical connector for connection to the fan control system.

The principle of operation of the sensor is based on the phenomenon of deformation of the bimetallic plate when the temperature changes. A bimetallic plate is two plates of metals attached to each other that have different coefficients of thermal expansion. As the temperature rises, the metals expand in different ways, as a result, the bimetallic plate bends and moves the movable contact - the circuit closes (or opens with normally closed contacts), the fan begins to rotate.

The sensor connection is similar to the one described above. Sensors of this type are the least common due to their higher price and complexity.

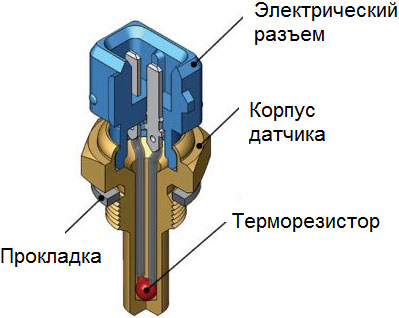

Design and principle of operation of the electronic sensor

Structurally, this sensor is also extremely simple: it is based on a thermistor placed in a massive metal case with a thread for screwing into the radiator and an electrical connector.

The principle of operation of the sensor is based on the effect of changing the electrical resistance of the thermistor when the temperature changes. Depending on the type of thermistor, its resistance may decrease or increase with increasing temperature. The change in the resistance of the thermistor is monitored by an electronic circuit, which, when a certain temperature is reached, sends control signals to turn on, change the speed of rotation or turn off the fan.

Structurally, this sensor is also extremely simple: it is based on a thermistor placed in a massive metal case with a thread for screwing into the radiator and an electrical connector.

The principle of operation of the sensor is based on the effect of changing the electrical resistance of the thermistor when the temperature changes. Depending on the type of thermistor, its resistance may decrease or increase with increasing temperature. The change in the resistance of the thermistor is monitored by an electronic circuit, which, when a certain temperature is reached, sends control signals to turn on, change the speed of rotation or turn off the fan.

Post time: Aug-24-2023