Normal operation of the pneumatic system is possible provided that clean, dry air circulates in it. For this purpose, an air dryer with a replaceable filter cartridge is introduced into the system. What is a dehumidifier filter cartridge, how it works and works, how to choose and replace it - read the article.

What is a dehumidifier filter cartridge?

The filter-cartridge of the air dryer is a replaceable element (cartridge) of the adsorption dehumidifier of the pneumatic system of vehicles, automotive, construction and other equipment. The filter cartridge removes moisture from the compressed air entering the system from the compressor, preventing a number of negative consequences:

• Reducing the risk of corrosion of pneumatic components of the pneumatic system;

• Prevention of freezing of the system in the cold season;

• Additional air purification from dirt and oil.

Replaceable cartridges are used only in adsorption dehumidifiers, being their main part (the second part of the dehumidifier is a body with valves, channels and pipes for connecting to the system). Tubular moisture and oil separators, still used on domestic trucks, have a completely different principle of operation and design, and they do not need filters.

Types of dehumidifier filter cartridges

The applied filter-cartridges are divided into groups according to the purpose / functionality, dimensions and characteristics of the connecting thread.

According to the purpose and functionality, there are two types of dehumidifier cartridges:

• Conventional (standard) - intended only for dehumidification of air;

• Coalescent (with an additional oil separator function) - designed to dry the air and remove oil droplets.

The most common today are conventional filter cartridges, since pneumatic systems usually have special elements to remove oil that enters the compressed air during the passage of the compressor. However, many manufacturers offer dehumidifier cartridges with a built-in oil separator, which acts as an additional degree of air purification from oil droplets.

In terms of dimensions, filter cartridges are standardized, they are of two main types:

• Standard – height 165 mm;

• Compact - 135 mm high.

Operation of the coalescent filter-cartridge of the dehumidifier

The diameter of all types of cartridges lies in the range of 135-140 mm. The most commonly used standard large filter cartridges, compact cartridges are used on commercial vehicles with a low-performance pneumatic system.

Filter cartridges are manufactured with metric threads of two main sizes:

• 39.5x1.5 mm;

• 41x1.5 mm.

In this case, the thread is right and left, which must be taken into account when choosing a cartridge for the dehumidifier.

Design and operation of the filter-cartridge of the air dryer

All filter-cartridges of dryers used today are adsorption - they are based on materials that have the ability to absorb moisture from the passing air flow. Granular or other fillers made of porous synthetic materials are used as such materials.

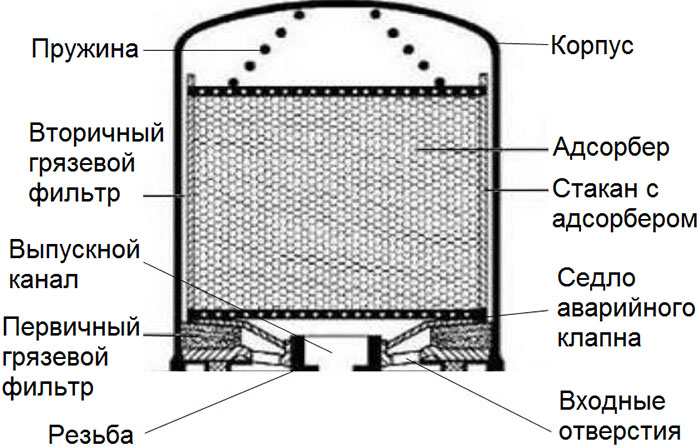

The design of the desiccant adsorption cartridge is simple. It is based on a stamped body, the upper part of which is deaf, and the bottom with one central threaded hole and a number of peripheral holes is pressed into the lower one. The peripheral openings are inlets, through which compressed air from the compressor enters the filter. The central hole is the outlet, from which the dried air enters the system, at the same time this hole is a connecting hole - with the help of a thread made on its walls, the cartridge is screwed onto the dehumidifier. The tightness of the cartridge's fit to the dryer housing is ensured by an annular rubber gasket (or two gaskets of large and small diameter).

The design of the filter-cartridge of the air dryer

Inside the case there is a metal cup with a granular adsorbent. The lower part of the glass rests on the bottom of the cartridge and has a tight connection with a threaded hole. Between the walls of the glass and the main body of the cartridge there is a gap for the free passage of air from the inlets, in this gap an additional dust filter can be located. In the upper part, the glass is closed with a perforated lid, against which the spring rests - this ensures reliable pressure of the glass to the bottom of the body.

An additional filter (usually made of fibrous materials) is provided at the bottom of the housing, which traps contaminants coming with air from the compressor. There is also an emergency valve seat (in the form of a metal cone on which the glass rests), which also includes a spring in the upper part of the glass with an adsorber. In coalescent filters, there is an additional check valve for draining oil in the lower part, it is made in the form of an elastic ring-cuff that allows air to pass through only in the regeneration cycle.

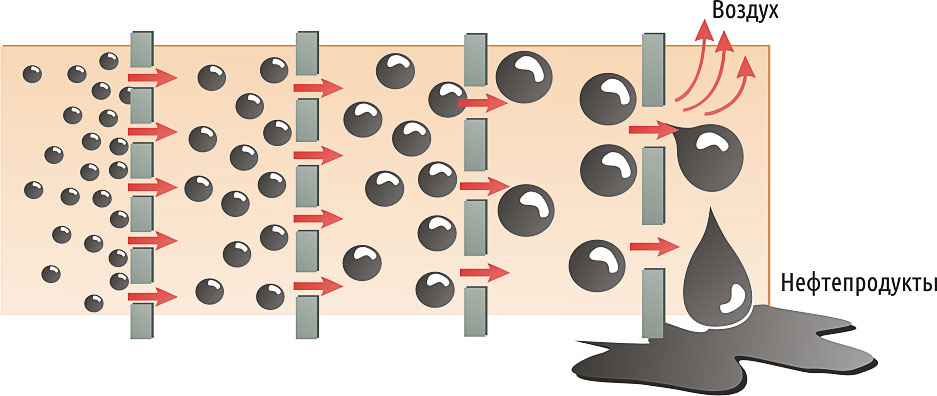

The process of coalescence is the separation of oil using a series of perforated plates

Coalescent filter cartridges have an additional ring multilayer filter located in the lower part of the body before entering the glass with an adsorber. This filter can be composed of a number of meshes with different mesh sizes or made of fibrous materials that allow free air to pass through. Passing through the holes in the filter, microscopic oil droplets increase in size and weight, and settle on it, flowing into the bottom of the cartridge. This process is called coalescence.

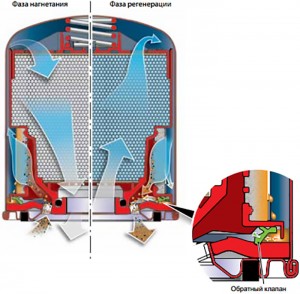

The principle of operation of filter-cartridges of dehumidifiers is simple.

Compressed air from the compressor enters through the peripheral openings into the cartridge, is pre-cleaned on a fiber filter, then enters the upper part of the glass with an adsorber. Here, the moisture contained in the air settles on the adsorber particles - the air is dried and enters the dryer housing through the central hole, from where it is fed through channels and valves to the pneumatic system. Similar processes take place in the coalescent filter, but here the air is additionally cleaned of oil, which gradually accumulates on the bottom of the case.

During the operation of the dryer, the adsorber of the filter-cartridge is saturated, its ability to absorb moisture decreases and the entire unit ceases to perform its functions normally. To restore the cartridge, a regeneration cycle is carried out, which is reduced to blowing compressed air in the opposite direction - through the central hole and the adsorber to the peripheral holes. The air source in this case is a special regeneration receiver. The air, passing through the adsorber, removes excess moisture from it and removes it into the atmosphere through a special valve in the dehumidifier. In the regeneration cycle of the coalescent filter cartridge, accumulated oil is also released into the atmosphere. After regeneration, the filter cartridge is ready for operation again.

Over time, the adsorber in the cartridge loses its qualities, it ceases to absorb moisture, and dirt penetrating through the filters accumulates between the granules. This leads to an increase in the resistance of the dehumidifier to the air flow, and, as a result, to a drop in pressure in the pneumatic system. To eliminate this problem, an emergency valve is built into the filter cartridge, the device of which is described above. When the adsorber is contaminated, the air flow exerts increased pressure on the bottom of the glass, it compresses the spring and rises, breaking away from the seat - the air passes into the resulting hole and enters directly into the system. In this mode, the air is not dehumidified, so the filter cartridge must be replaced as soon as possible.

How to choose and replace a dehumidifier filter cartridge

When selecting a filter cartridge, it is necessary to take into account its dimensions, connecting dimensions and functionality. First of all, you should start from the size of the connecting thread - it can be with a diameter of 39.5 and 41 mm. In most cases, the height of the filter also matters, although it is often possible to install a cartridge of a different type (standard instead of compact, and vice versa), which must be stated in the instructions.

Particular attention should be paid to replacing the filter with an oil separator. If a coalescent filter cartridge dryer is installed on the vehicle, it is recommended to change it to the same one. If a conventional filter is used, then in most cases it is permissible to use a coalescent filter - this will provide additional air purification from oil and extend the service of the pneumatic system.

It is recommended to change the filter-cartridges of the dehumidifier once a year or once every two years. If the vehicle is operated in conditions of high humidity and dust, then the dehumidifier cartridge must be changed more often. Here you should be guided by the recommendations of the manufacturer of the vehicle and cartridge.

With the right choice and timely replacement of the filter-cartridge of the air dryer, the pneumatic system of the car will work efficiently and reliably in any conditions.

Post time: Aug-22-2023