Most modern cars and other wheeled vehicles are equipped with a power steering system, in which there is always a container for storing liquid - an oil tank power steering. Read all about these parts, their types, design and features, as well as the selection and replacement of tanks in the article.

Purpose and functions of the power steering tank

The power steering oil tank (power steering tank) is a container for storing the working fluid of the power steering of wheeled vehicles.

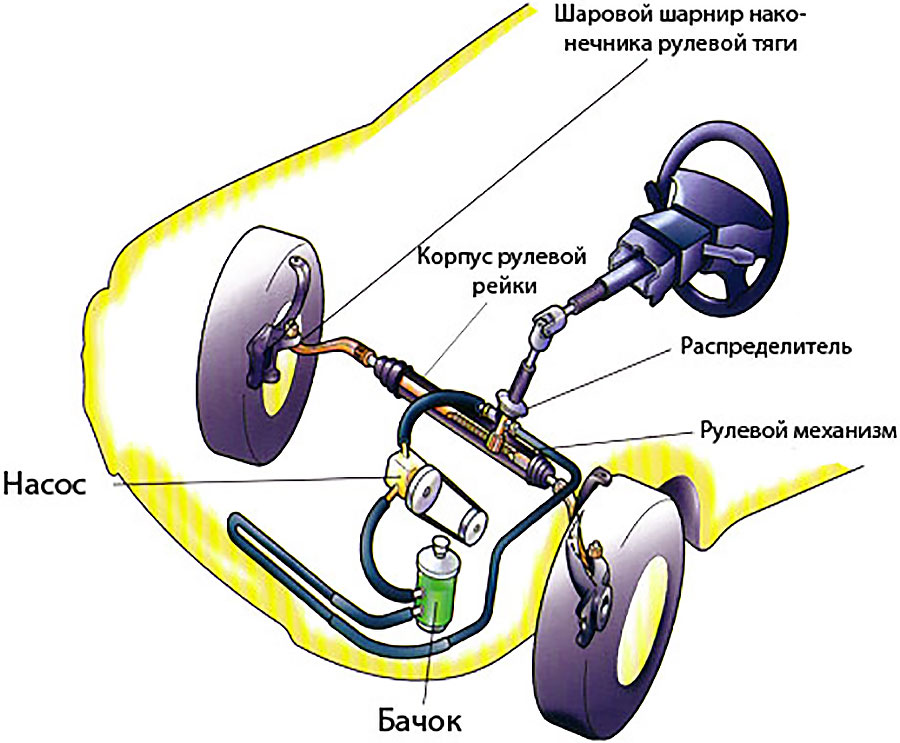

Modern cars and trucks, tractors and other equipment are mostly equipped with hydraulic power steering. In the simplest case, this system consists of a pump connected to the steered wheels of the steering mechanism and a rudder-controlled distributor. The entire system is combined into one circuit, through which a special working fluid (oil) circulates. To store oil, another important element is introduced into the power steering - an oil tank.

The power steering oil tank solves several problems:

● It is a container for storing a volume of oil sufficient for the functioning of the system;

● Compensates for the reduction in oil volume due to leaks;

● Compensates for the thermal expansion of the working fluid;

● Filter tank – cleans the oil from contaminants;

● Carries out pressure relief in case of its excessive growth (with an increased volume of liquid, clogging of the filter element, air entering the system);

● Metal tank - acts as a radiator for cooling the liquid;

● Provides various service functions - replenishment of the supply of working fluid and control of its level.

The power steering tank is a part without which the functioning of the entire system would be impossible. Therefore, if any malfunctions occur, this part should be repaired or replaced. And to do it right, you need to understand the existing types of tanks and their design features.

The general scheme of the power steering and the place of the tank in it

Classification of power steering oil tanks

Power steering tanks are classified according to the design and material of manufacture, the presence of a filter element and the place of installation.

By design, there are two types of tanks:

● Disposable;

● Collapsible.

Non-separable tanks are usually made of plastic, they are not serviced and have a limited resource, in the development of which they must be replaced in the assembly. Collapsible tanks are most often made of metal, they are regularly serviced during operation and can be repaired, so they can serve on the car for years.

According to the presence of a filter, tanks are divided into two categories:

● Without filter;

● With filter element.

The design of the power steering tank with a built-in filter

Tanks without a filter are the simplest solution, which is rarely used today. The absence of a built-in filter dramatically reduces the service life of the working fluid and requires the installation of a separate filter, and every extra detail complicates the system and increases its cost. At the same time, these tanks, as a rule, have a built-in coarse filter - a mesh on the side of the filler neck, which prevents large contaminants from entering the system.

Tanks with a built-in filter are a more modern and common solution today. The presence of a filter element ensures the timely removal of all contaminants (particles of wear of rubbing parts, corrosion, dust, etc.) from the working fluid, and, as a result, the extension of its service life. Filters can be of two types:

● Replaceable (disposable) filters made of paper and nonwovens;

● Reusable strainers.

Replaceable filters are standard ring filters made of pleated filter paper or nonwovens. Such elements are used in both collapsible and non-collapsible tanks. Reusable filters are typesetting, consist of a number of steel meshes with a small mesh assembled in a package. In case of contamination, such an element is disassembled, washed and installed in place. Replaceable filters are easier to maintain than reusable filters, so today they are widely used.

At the place of installation, there are two types of power steering tanks:

● Individual;

● Integrated with the pump.

Separate tanks are made in the form of independent blocks, which are connected by two pipelines to the power steering pump and steering mechanism. Such tanks can be installed in any convenient place, but require pipes or hoses, which somewhat complicates the system and reduces its reliability. Tanks integrated with the pump are more often used on trucks and tractors, they are mounted directly on the pump, without requiring additional connections. Such tanks provide increased reliability of the system, but their placement is not always convenient for maintenance.

Replaceable power steering tank filter Power steering

pump with integrated oil tank

Design and features of non-separable power steering tanks

Non-separable tanks are made of two molded plastic halves soldered into one sealed structure of cylindrical, prismatic or other shape. In the upper part of the tank there is a screw or bayonet filler neck in which the plug is installed. A filter mesh is usually installed under the neck. In the lower part of the tank, two fittings are cast - exhaust (to the pump) and intake (from the steering mechanism or rack), connected to the mechanisms of the system using hoses. A filter element is installed at the bottom of the tank, it can be pressed using a plate on a screw or latches. The filter is installed so that it receives used oil from the steering mechanism, where it is cleaned and then supplied to the pump..

The lid of the tank has built-in valves - inlet (air) for supplying outside air, and exhaust valves for venting excessive pressure and removing excess working fluid. In some cases, there is a dipstick under the lid with marks of the maximum and minimum oil level. In tanks made of transparent plastic, such marks are most often applied on the side wall.

Steel clamps or plastic brackets cast on the wall are used to mount the tank. Fixing the hoses on the fittings is carried out with metal clamps.

Design and features of collapsible power steering tanks

Collapsible tanks consist of two parts - the body and the top cover. The lid is installed on the body through a rubber seal, its fixation is carried out with the help of a stud passed from the bottom and a nut screwed onto it (ordinary or "lamb"). A filler neck is made in the lid, sometimes a separate neck is provided for the installation of a safety valve. The filler neck is closed with a stopper similar to the one described above.

In separate tanks, a filter element is located on the bottom, and a strainer is located under the filler neck. As a rule, the filter element is pressed to the bottom by means of a spring resting on the strainer or directly on the filler cap. This design is a safety valve that ensures the flow of oil directly into the pump when the filter is excessively dirty (when the filter is dirty, the fluid pressure rises, at some point this pressure exceeds the spring force, the filter rises and the oil flows freely into the exhaust fitting).

In the tanks integrated into the pump, an additional manifold is provided - a massive part with channels located in the lower part and designed to supply oil to the pump. Usually, in such tanks, the filter is located on a stud that fixes the top cover.

How to choose, repair or replace a power steering tank

The power steering tank is highly reliable and durable, but it must be regularly inspected (with maintenance of the entire system), and if malfunctions are detected, it can be repaired or replaced in the assembly. Periodically, it is necessary to change non-separable tanks and replace / flush filter elements in collapsible structures - the frequency of maintenance is indicated in the instructions, usually the service interval reaches 40-60 thousand km, depending on the type of vehicle.

Obvious signs of a tank malfunction include oil leaks (lowering its level and the appearance of characteristic puddles under the car when it is parked), the appearance of noise and deterioration of the steering. When these signs appear, you should check the tank and the entire power steering, you need to pay attention to the body of the tank and its fittings for cracks. And in the tanks installed on the pump, you need to inspect the seal, which, due to various reasons, can leak. Sometimes problems arise with filler plugs. If any malfunctions are detected, the power steering tank should be repaired or replaced in the assembly.

For replacement, you need to take the tanks recommended for installation on the car. In some cases, it is possible to install other parts, but with such a replacement, the operation of the entire system may deteriorate due to a different throughput of the filter tank. Replacement of the tank is carried out in accordance with the instructions for repair and maintenance of the vehicle. These operations are preceded by draining the working fluid and flushing the system, and after repair, it is necessary to fill in new oil and bleed the system to remove air plugs.

With the correct selection of the tank and its competent replacement, the entire power steering will work efficiently and reliably, providing comfortable driving.

Post time: Jul-11-2023