Most modern chain-driven engines use hydraulic chain tensioners. Everything about hydraulic tensioners, their existing designs and features of work, as well as the correct selection and replacement of these devices - read the article proposed on the site.

What is a hydraulic timing chain tensioner?

Hydraulic timing chain tensioner (hydraulic chain tensioner) is an auxiliary unit of the chain drive of the gas distribution mechanism; hydraulic cylinder of a special design that provides the necessary in magnitude and constant in time (independent of current temperature conditions, loads and wear of parts) interference of the chain.

The chain drive of the camshaft is still widespread, which is due to its reliability and resistance to high loads. However, the chain is subject to thermal expansion (as it is made of metal), and over time it wears out and stretches - all this leads to a change in the interference of the chain, which is manifested by an increase in vibrations and noise, and ultimately can result in slipping along the teeth of the stars, changing phases and even destroying individual parts. All these problems are solved by using a special device - a hydraulic chain tensioner.

The hydraulic tensioner performs two key functions:

● Automatic maintenance of the chain interference when it is worn and pulled;

● Damping the vibrations of the circuit branch during engine operation.

The use of this device makes it unnecessary to manually adjust the degree of interference of the chain, and eliminates the negative effects of gradual wear of drive parts. Also, due to its design, the hydraulic tensioner dampens vibrations and vibrations of the chain, reducing the load on the parts and the overall noise level of the mechanism. A faulty hydraulic tensioner can be a source of problems, so it needs to be replaced as soon as possible. But before buying or ordering a new hydraulic chain tensioner, you should understand the design and operation of these devices.

Hydraulic Chain Tensioner Design Hydraulic Chain

Types, design and principle of operation of hydraulic chain tensioners

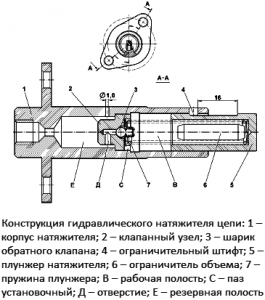

Scheme of operation of the spring-hydraulic chain tensioner of VAZ engines

In principle, all modern hydraulic tensioners have the same structure and principle of operation, differing only in details and additional functionality. The unit consists of a metal cylindrical body, in front of which there is a plunger, and in the rear - a valve assembly. A closed working cavity is formed between the plunger and the valve assembly. The plunger is made in the form of a hollow cylinder that can move along the body, it is spring-loaded, in its front part there is a surface for stopping in a shoe or lever with a chain tensioner sprocket. The plunger is protected from slipping out of the body by a pin or a special locking mechanism. The valve assembly carries a check valve located on the side of the plunger. The valve is made of a spring-loaded ball that closes the oil supply channel. The ball can only move towards the working cavity.

Tensioner Design Without Reserve Cavity

A mounting flange is made on the tensioner body, and a threaded hole is also provided for attaching a tube or hose from the engine lubrication system. The device is mounted next to the chain, its plunger rests against the shoe or sprocket lever, due to which the force is evenly transmitted to the timing chain.

The hydraulic tensioner works as follows. When the engine starts, pressurized oil is supplied to the check valve and, having overcome the spring force, is supplied to the working cavity. Under the action of the created pressure, the plunger extends from the body and rests against the shoe or sprocket lever. A moving plunger creates a force under which the chain is pulled, but at some point the interference reaches its maximum value - the oil pressure in the working cavity is no longer enough for further movement of the plunger. At this point, the chain already creates pressure on the plunger, and at some point the oil pressure in the working cavity is compared with the pressure of the oil coming from the engine lubrication system - this leads to the closure of the check valve. In this way, the oil is locked in the working cavity, the plunger can no longer move, the chain remains in a tight position. When the motor stops, such a tensioner remains in the working position, preventing the chain interference from weakening.

Gradually, the timing chain is pulled out, which leads to a decrease in the pressure exerted by it on the plunger. At some point, the pressure in the working cavity becomes lower than the pressure from the engine lubrication system - this leads to unlocking the check valve and repeating all the processes described above. Under the action of oil pressure, the plunger extends slightly from the housing and compensates for the stretching of the chain, when the chain interference reaches the required value again, the check valve will close.

It should be noted that during engine operation, the tensioner acts as a damper - the oil closed in the working cavity partially absorbs shocks and chain vibrations transmitted to the plunger. This reduces the noise of the drive and increases the life of its parts.

Today, there are several modifications of the hydraulic tensioners of the chain, differing in some design features.

Hydraulic tensioners with a reserve cavity. In such devices, there is another cavity behind the valve assembly, in which there is a small amount of oil - this improves the operation of the chain tension mechanism in transient engine modes and in other situations. Also, a small hole is made in the reserve cavity for bleeds, which prevents the oil from airing in the working cavity.

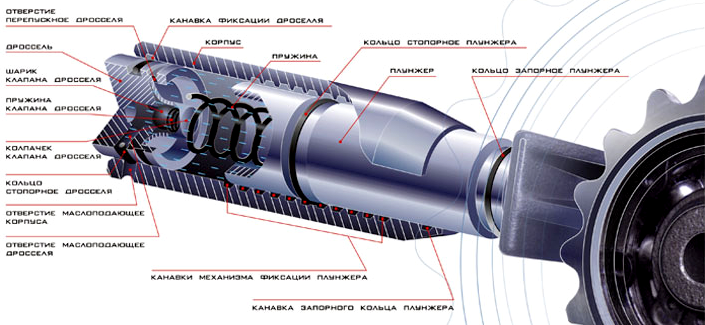

Hydraulic tensioners with a plunger locking mechanism based on a locking ring and grooves. In such devices, annular grooves are made inside the case, located at a certain distance from each other, and a retaining ring is located on the plunger. When the plunger moves, the retaining ring jumps from groove to groove, which achieves the installation of the part in a fixed position.

Hydraulic tensioners with bypass throttle (draining oil into the system). In such devices, the valve assembly has a throttle (small diameter hole), which ensures that the oil is drained from the working cavity back into the engine lubrication system. The presence of a throttle improves the damping qualities of the tensioner and allows the plunger not only to move forward, but also to partially sink into the body with a short-term increase in chain tension.

Today, all of these devices are used on engines. Usually, one hydraulic tensioner ensures the normal operation of only one chain, so one tensioner is used on motors with one timing chain, and two with two chains. Parts can be supplied separately or assembled with brackets, shoes and other auxiliary devices. Many tensioners are equipped with a protective check that prevents the spontaneous extension of the plunger during transportation, this check is removed when the part is mounted on the motor. There are other designs, but in general they work in the way described above, differing only in some details.

How to choose and replace the timing chain hydraulic tensioner

The hydraulic tensioner is subjected to significant loads, so over time it can lose tightness or fail due to breakage of the valve, spring and other parts. The malfunction of this part is manifested by the increased noise of the timing chain drive, and upon direct inspection (which requires partial disassembly of the engine), it is detected by weakening the chain, immobility or, conversely, too free movement of the plunger. A defective tensioner must be replaced as soon as possible.

A replacement part of the same type and model that was installed earlier (determined by the catalog number) should be taken. The use of a different type of hydraulic tensioner can cause insufficient or excessive interference of the chain and deterioration of the entire drive. Therefore, a "non-native" device should be installed only in cases where it exactly corresponds to the "native" one in terms of characteristics.

Hydraulic chain tensioner with plunger locking mechanism and oil reverse drain

Repair work must be carried out in accordance with the instructions for the engine. Usually, to replace the tensioner, you need to access the timing drive (which requires removing the front engine cover, and sometimes carrying out a more serious disassembly of the unit), and simply unscrew the two bolts holding this part. Then a new tensioner is put in its place, and, if necessary, additional parts (gaskets, seals, intermediate parts between the plunger and the shoe / lever of the pressure sprocket, etc.). The new tensioner should not be filled with oil, and its plunger should not be manually extended, otherwise the device may not provide the desired chain interference after starting the engine. After replacing the part, check the oil level in the lubrication system and, if necessary, bring it to normal.

At the first start of the motor after repair, the noise of the chain will be heard from the drive side, but after a few seconds - when the working cavity of the tensioner is filled and the plunger is in the working position - it should disappear. If the noise does not disappear, then the installation of the part is incorrect or there are other malfunctions. With the correct selection and replacement of the hydraulic tensioner, the chain will always have an optimal interference, and the timing of the motor will work confidently in all modes.

Post time: Jul-13-2023