One of the main parts of the ignition distributor is the base plate, which is responsible for the functioning of the breaker. Everything about breaker plates, their existing types and design features, as well as the selection, replacement and adjustment of these components is described in detail in this article.

What is an ignition distributor plate

The ignition distributor plate (breaker base plate) is a component of the ignition breaker-distributor (distributor); A metal plate that acts as a support for the contact group of the breaker or stator distributor of the contactless ignition system.

In carburetor and some injection gasoline engines, the ignition system is built on the basis of a mechanical device - a breaker-distributor, which is often called simply a distributor. This unit combines two devices: a breaker that forms a series of short current pulses, and a distributor that ensures the timely supply of these pulses to the engine cylinders (performs switching functions). Various systems are responsible for the formation of high-voltage pulses in distributors:

● In the contact ignition system - a breaker built on a contact group, periodically opened by a rotating cam;

● In a contactless ignition system, a sensor (Hall, inductive or optical) that generates control signals for the switch, which, in turn, generates high-voltage pulses in the ignition coil.

Both systems - both the conventional contact breaker and the sensor - are located directly in the housing of the ignition distributor, they are mechanically connected to the distributor rotor. In both cases, the support of these systems is a special part - the breaker plate (or ignition distributor plate). This part plays an important role in the performance of the entire distributor, its failure usually disrupts the functioning of the ignition system. A faulty plate must be repaired or replaced, but in order to make a competent repair, it is necessary to understand the existing types of breaker plates, their design and features.

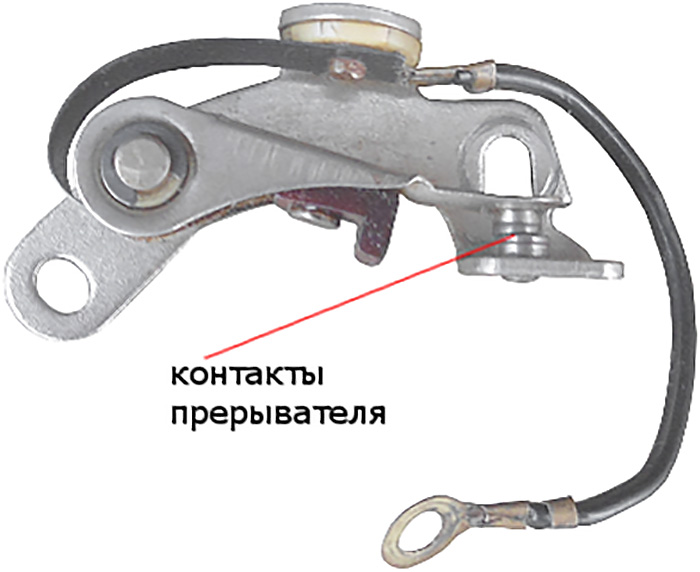

Breaker contact group

Types, design and principle of operation of the ignition distributor plate

The breaker plates are divided into two groups according to the type of ignition distributor:

● For contact distributor;

● For contactless distributor.

Parts have significant differences from each other in design and operation.

Breaker plates for contact ignition system

There are two types of distributor breaker base plates for the contact ignition system:

● Plates without bearing cage;

● Plates aligned with the bearing cage.

Distributor design with separate base plate and contacts

The simplest design is the plates of the first type. The basis of the design is a stamped steel plate of complex shape, in the center of which a round hole is formed with a collar for fitting the bearing. The plate has threaded and simple holes for mounting the contact group and the stand with a felt strip for lubricating and cleaning the shaft, as well as a wedge-shaped hole at the installation site of the contact group for adjusting the gap between its contacts. The plates are supplied with a bearing mounted on a collar and a mass wire with a terminal of one type or another. Breaker plates of this type were widely used in distributors installed on VAZ "Classic" cars and some others, in such units this part is called the "movable breaker plate".

A more complex design has the plates of breakers of the second type. Structurally, this part consists of two elements: a movable breaker plate and a bearing cage. The movable plate has a design similar to that described above, under it there is a bearing cage - also a stamped steel part, on the sides of which legs are formed with holes for mounting in the distributor housing. A bearing is located between the movable plate and the cage, a contact group with a wire and a felt strip are mounted on the movable plate, and a mass wire is connected to the cage.

Both types of plates are mounted at the bottom of the ignition distributor housing. The plate without the bearing cage is installed directly in the housing, which acts as a cage. The second type of plate is fixed in the housing with screws screwed into the bearing cage. The movable plates are connected to the vacuum corrector by means of traction, thereby changing the ignition timing depending on the engine operating mode.

Contact type igintion distributor plate

The distributor plates in the contact ignition system work as follows. The plate ensures the correct location of the contact group relative to the distributor shaft. When the shaft rotates, its cams hit the movable contact, providing a short-term interruption of the current, due to which high-voltage pulses are created in the ignition coil, which are supplied to the distributor and then to the candles in the cylinders. When changing the operating mode of the engine, the vacuum corrector rotates the movable plate at a certain angle in one direction or another, which achieves a change in the ignition timing. Smooth rotation of the plate while maintaining sufficient rigidity of the structure is provided by the bearing.

Plates of contactless ignition distributors

There are three main types of contactless distributor plates:

● With Hall sensor;

● With inductive sensor;

● With optical sensor.

In all cases, the basis of the part is a stamped steel plate on which a sensor or other device is installed. The plate is mounted through the bearing in the distributor housing and connected to the vacuum corrector by a rod, and conductors are also located on the plate to transmit the generated control signals to the switch.

Contactless type igintion distributor plate

Depending on the type of distributor, various parts can be located on the plate:

● Hall sensor - a device with a Hall chip, in which a groove is made for the rotor connected to the distributor shaft;

● A multi-turn coil is a round coil that is the basis of an inductive type sensor, a magnet connected to the distributor rotor acts as a rotor in such a sensor;

● An optical sensor is a device with an LED and a photodiode (or photoresistor), which are separated by a groove for a rotor with cutouts connected to the distributor shaft.

The most widely used are sensors-distributors built on the basis of the Hall sensor - they can be found on VAZ cars and many trucks. Inductive sensors are used much less frequently, such distributors can be found on GAZ-24 cars and some later Volga, individual UAZ models and others. Optical sensors-distributors on domestic cars are practically not used, they can be seen on some foreign-made cars with carburetor engines.

How to choose and replace the ignition distributor plate

During the operation of the distributor, the breaker plate is subjected to mechanical and thermal loads, which leads to gradual wear of its parts (primarily the contact group), deformations and damage. All this is manifested by the deterioration of the ignition system, including a spontaneous change in the ignition timing or the inability to adjust it, the appearance of interruptions in the operation of individual cylinders, deterioration of starting, etc.

For replacement, you should take the breaker plate only of the type (catalog number) that was installed in the distributor earlier, or recommended by the distributor manufacturer. To install a new plate, it is necessary to dismantle and disassemble the distributor (since this part is located at the bottom of the unit, you have to remove the distributor and regulator to access it) - this must be done in accordance with the instructions for repairing a particular engine or car. The new plate should fall into place without any effort and rotate freely in the bearing. During installation, attention should be paid to the connection of the plate with the vacuum corrector and with all electrical terminals.

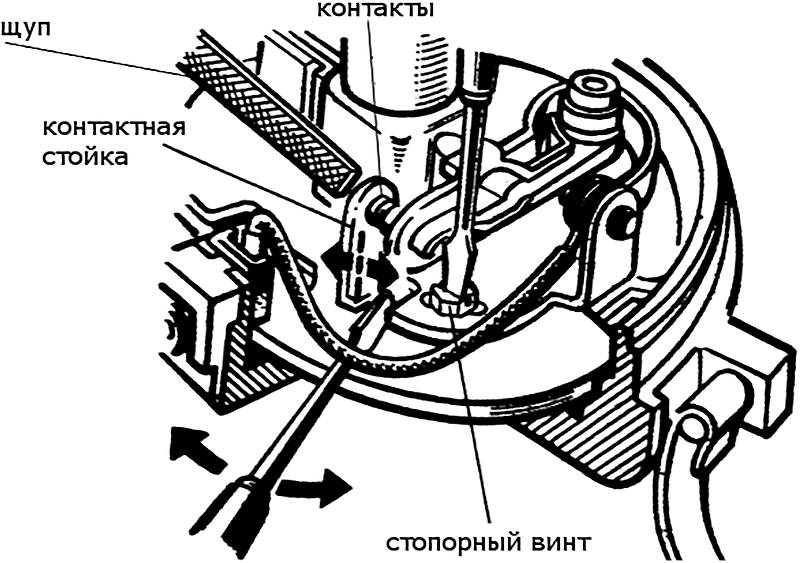

Adjustment of the distributor contact group

During the operation of the distributor, problems may appear that are not related to the condition of the plate, but caused by a change in the gap between the contacts of the breaker. To solve this problem, you should partially disassemble the distributor by removing the cover, and measure the gap between the contacts - it should lie within the limits set by the manufacturer of this distributor. If the gap differs from the installed one, then it is necessary to loosen the screw attaching the contact group to the plate and adjust the gap, and then tighten the screw. It may also be necessary to clean the contacts from soot with a sandpaper.

With the correct selection and replacement of the breaker-distributor plate or distributor sensor, the ignition system will function confidently and reliably in all engine operating modes.

Post time: Jul-10-2023