On the current modifications of KAMAZ engines, an oil cooling system is provided, built on one unit - an oil heat exchanger. Read all about these parts, their types, design, principle of operation and applicability, as well as the right choice, repair and replacement of heat exchangers in this article.

What is a KAMAZ oil heat exchanger?

Oil heat exchanger (liquid-oil heat exchanger, LMT) is a unit of lubrication and cooling systems for high-power diesel power units; A specially designed heat exchanger built into the engine liquid cooling system, which provides cooling of the engine oil due to heat exchange with the coolant flow.

The lubrication system of powerful KAMAZ diesel units operates in difficult conditions, the oil is constantly exposed to high temperatures and gradually loses its qualities. In certain modes, engine oil can overheat, which leads to a decrease in its viscosity and lubricity, as well as to intense decomposition and burnout. Ultimately, overheated oil impairs the performance of the engine and can even cause it to fail. This problem is solved by introducing an oil cooling element — a heat exchanger — into the lubrication system of KAMAZ engines.

The oil heat exchanger is an integral part of the engine lubrication and cooling systems, it ensures the removal of excess heat from the oil due to active heat exchange with the coolant washer flow (coolant). That is why devices of this type are called liquid-oil heat exchangers, or LMT. This unit performs several functions:

- Partial cooling of the oil at an engine temperature of less than 100 degrees;

- Cooling of all oil entering the engine at a temperature in the range of 100-110 degrees;

- Reducing oil consumption for waste and extending its life;

- Ensuring the optimal temperature regime of various engine systems - thanks to LMT, the oil temperature never drops below the coolant temperature, which contributes to a more uniform heating of engine parts, reduction of mechanical stresses, etc.;

- Simplifying the design of the oil cooling system and reducing the cost of the engine while ensuring the normal characteristics of its operation.

Today, heat exchangers are installed in most KAMAZ diesel engines that meet Euro-2 standards and above, they play an important role in ensuring the normal characteristics of the power unit in all operating modes. A faulty heat exchanger must be repaired or completely replaced as soon as possible, but before buying a new part, you should understand the design and operation of these devices.

Design and principle of operation of KAMAZ oil heat exchangers

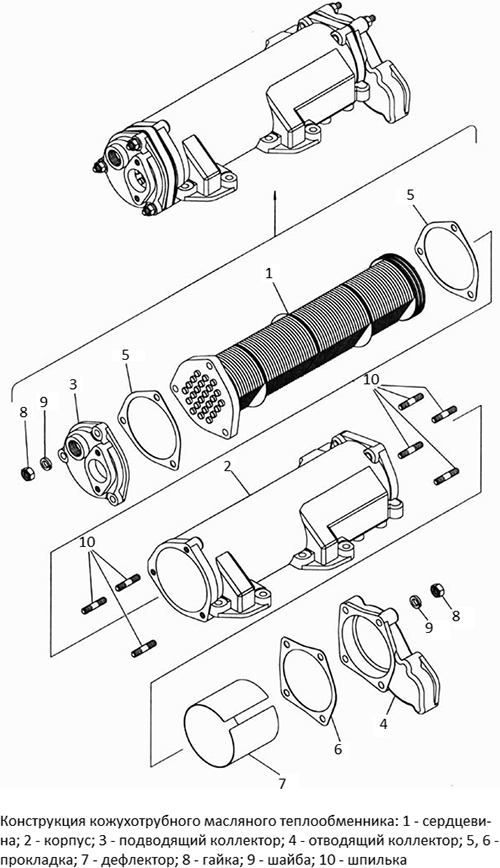

On KAMAZ engines, only shell-and-tube (tubular) type shell-and-tube (tubular) type of various modifications are currently used. Structurally, this unit is quite simple, it consists of the following parts:

● Body (casing);

● Core with deflector;

● Inlet manifold;

● Discharge manifold.

The basis of the design is an aluminum cylindrical body (casing), on the wall of which channels and filler surfaces are made for connecting to the oil filter block (installation is carried out through gaskets). The ends of the casing are closed with special covers with nozzles - inlet and outlet manifolds, the first provides coolant from the water jacket of the cylinder block inside the housing, and the second diverts the liquid back to the engine cooling system. Drilling and channels are made on the body for the installation of bypass valves, which ensure that the oil bypasses bypassing the heat exchanger when its core is clogged.

A core is installed inside the case - an assembly of thin-walled copper or brass tubes placed in a package of transverse metal plates. On the core there are five plates with a protruding part, which divide the entire part into four sections, which provides a change in the direction of oil flow. On one side of the core there is a flange, which, during installation, rests on the end of the body, on the opposite side the flange has such a diameter as to fit tightly into the casing, and there are several O-rings on it. This design ensures the separation of the flow of coolant and oil, preventing them from mixing. And for the correct direction of oil flow, a deflector is located on one side of the core - an open metal ring with a slot.

The design of the KAMAZ oil heat exchanger

In the assembled LMT, a heat exchanger with two isolated flows is formed: coolant flows through the core tubes, and oil flows through the space between the tubes and the walls of the casing. Due to the separation of the core into four sections, the oil flow path is increased, which achieves a more efficient heat transfer of the coolant.

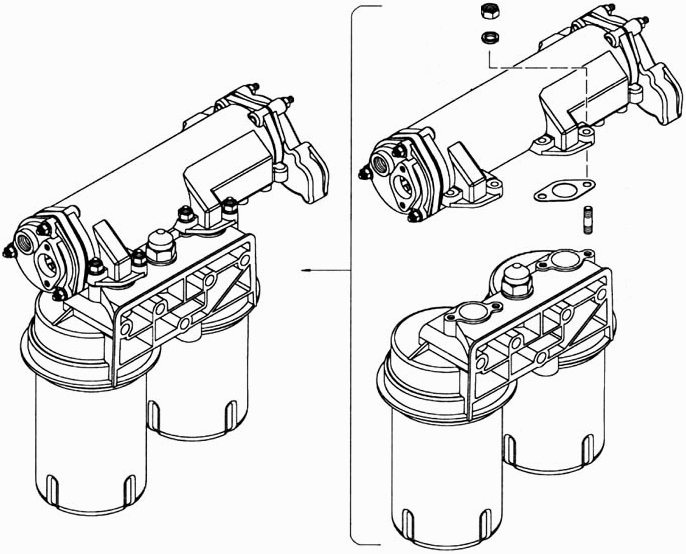

LMT is mounted on the engine assembly with an oil filter block (a thermopower valve that regulates the flow of oil through the heat exchanger is also located here), its supply and outlet manifolds are connected to the corresponding pipes on the cylinder block. In most designs, the supply manifold is connected to the block by means of a short pipe, and the discharge manifold is connected by means of a filler surface.

LMT works as follows. When the engine temperature is below 95 degrees, the thermal power valve is closed, so the entire oil flow from the oil pump passes through the filters and immediately enters the engine lubrication system. When the temperature rises above 95 degrees, the valve opens, and part of the oil from the filters is sent to the LMT - here it passes inside the casing around the core, gives off excess heat to the coolant passing through the pipes, and only then enters the engine lubrication system. When the temperature rises above 100 degrees, the thermal valve directs the entire flow of oil from the filters to the LMT. If for any reason the engine temperature has exceeded 115 degrees, the cooling of the oil in the LMT becomes ineffective and overheating may occur - the corresponding indicator on the dashboard warns of the onset of an emergency.

Applicability of oil heat exchangers on KAMAZ vehicles

LMTs are installed only on KAMAZ 740 diesel engines of various modifications of Euro-2, 3 and 4 environmental classes. Two types of heat exchangers are used today:

● Catalogue number 740.11-1013200 - short modification;

● Catalog number 740.20-1013200 is a long modification.

The difference between these parts lies in the design of the collectors and, consequently, in the method of connection to the cooling system. In a short LMT, the discharge manifold has only a filler surface at the end for attaching the pipe using bolts or studs. Heat exchangers with such a manifold are universal, they are suitable for most KAMAZ engines of various environmental classes. In a long LMT on the outlet manifold there is a pipe for connecting a hose with a metal clamp. Otherwise, both parts are identical and can be attached to standard filter assemblies.

Installation of a KAMAZ oil heat exchanger on an oil filter unit

Also, in the parts of the heat exchanger, as a result of corrosion processes or damage, cracks and crevices occur through which the oil enters the coolant. The same problem is observed when the sealing elements are worn or damaged. In this case, the LMT must be repaired or completely replaced. Today, there are various repair kits on the market containing gaskets, cores, manifolds and other parts. If the repair is impossible or impractical, then it is necessary to completely replace the part. All work is carried out in accordance with the instructions for the repair and maintenance of the vehicle. Before repair, the coolant and part of the oil are drained, after replacement, all fluids are brought to the desired level. Subsequently, LMT requires only regular inspection and verification of valves during each routine maintenance.

If the heat exchanger is selected and installed correctly, then the engine oil will always have an optimal temperature, ensuring the efficient operation of the power unit

Post time: Jul-13-2023