Moving cargo over short distances when it is impossible to use special equipment can be a real problem. Hand winches come to the rescue in such situations. Read all about hand winches, their types, design and characteristics, as well as the choice and use of these devices in the article.

What is a hand winch

A hand winch is a hand-operated lifting and transport (lifting) mechanism designed for horizontal and, to a lesser extent, vertical movement of various loads.

When performing loading and unloading operations, significant efforts are required to pull out stuck vehicles and machines, to move goods from place to place. For such work, you can use special lifting equipment, but this is not always possible. In situations where special equipment is not available, and the required effort does not exceed several tons, simple lifting and transport mechanisms with a manual drive come to the rescue - hand winches.

Hand winches can be used in a variety of situations:

● Pulling out cars, tractors, machines and other equipment stuck on the roads;

● Movement and lifting of goods on construction sites;

● Performing basic and auxiliary operations during loading and unloading operations in the absence of ● electric winches and special equipment, as well as in confined spaces.

It should be noted that at present there are two groups of lifting and transport mechanisms similar in functionality: winches used mainly to move goods in the horizontal plane, and hoists used to move goods in the vertical plane. This article covers only manually operated winches.

Types, design and characteristics of hand winches

Hand winches are divided into two large groups according to the principle of operation:

● Spires (drum, capstans);

● Installation and traction mechanisms (MTM).

At the heart of spire (drum) winches is a drum on which a cable or tape is wound, traction is created when the drum rotates. At the heart of the MTM is a pair of clamping blocks that provide clamping and pulling of the cable, thereby creating traction. All these winches have their own design features.

Spire winches are divided into several types according to the method of transferring force to the drum:

● Gear;

● Worm;

● Lever.

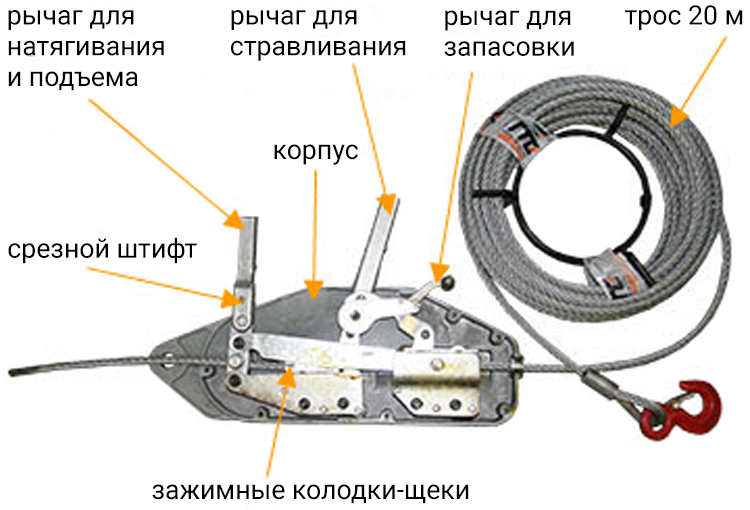

The device of the mounting and traction mechanism

Gear and worm hand winches are often referred to simply as drum winches. Structurally, such winches are simple. The basis of the gear winch is a frame in which a drum with a rigidly fixed cable and a large gear at one of the ends is installed on the axle. On the frame there is a handle connected to a small gear, which engages with the gear on the drum. Also, a ratchet stop mechanism is associated with the handle or drum - a gear wheel and a movable spring-loaded pawl that can lock the mechanism, and, if necessary, release it. When the handle rotates, the drum also comes into rotation, on which the cable is wound - this creates a tractive force that sets the load in motion. If necessary, the winch is locked by a ratchet mechanism, which prevents the drum from spontaneously turning in the opposite direction under load.

The winch with a worm mechanism has a similar design, but in it a pair of gears is replaced by a worm pair, the worm of which is connected to the drive handle. Such a winch can create a lot of effort, but it is more difficult to manufacture, so it is less common.

Winches of gear and worm type are most often stationary - their frame is rigidly fixed on a fixed base (in the wall, on the floor, on the frame of a car or other vehicle).

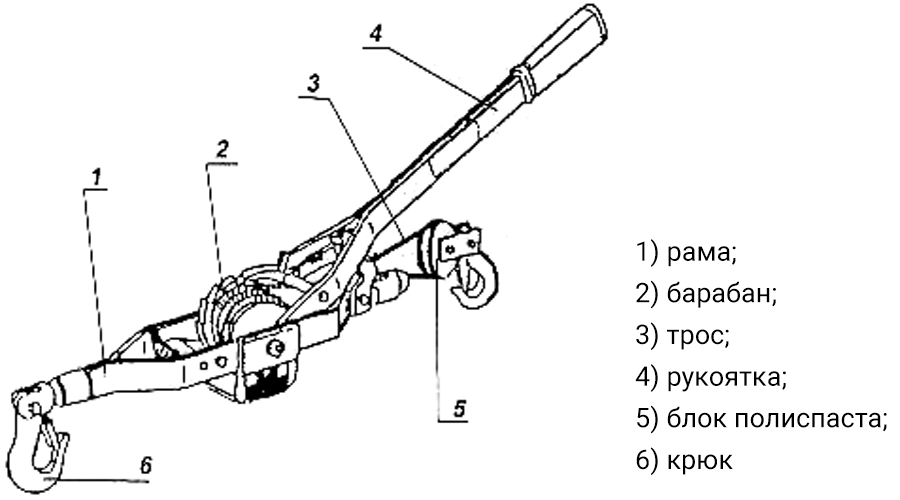

Lever winches have a simpler device. They are also based on a frame, in which a drum with a cable is located on the axis, on one or both ends of which gears are fixed. A lever is also installed on the axis of the drum, on which one or two pawls are hinged - they, together with the gear wheel (wheels) of the drum, form a ratchet mechanism. The lever can have different lengths, be rigid or telescopic (variable length). Next to the drum, one or two more pawls are installed on the frame - they, together with the gears, form a stop mechanism that ensures that the drum locks under load. On one side of the frame, a hook or anchor pin is hinged, with the help of which the winch is fixed on a fixed object, on the other side there is a cable wound on the drum and having a rigid connection with it.

Manual lever wire rope winch

The device of a manual lever winch with a polyspast block

The lever winch also works very simply: when the lever moves in one direction, the pawls rest against the gears and turn the drum with them - this creates a tractive force that ensures the movement of the load. When the lever moves back, the pawls freely slip the teeth on the wheel, returning to their original position. At the same time, the drum is locked by the pawls of the stop mechanism, so the winch reliably holds the load under load.

Lever winches are usually portable (mobile), to perform lifting and transport work, they must first be fixed on a fixed base (wood, stone, some structure or a stalled vehicle), and then secure the load.

Gear, worm and lever winches are divided into two groups according to the type of cable used:

● Cable - equipped with a steel twisted cable of small cross-section;

● Tape - equipped with textile tape made of nylon or other synthetic materials.

Installation and transport mechanisms have a different design. They are based on a body in which there are two clamping blocks, each of which consists of two pads (cheeks). The blocks are connected by a clamping mechanism, which is a system of rods and levers connected to the drive arm, the reverse lever and the release lever of the rope mechanism. At one end of the winch body there is a hook or anchor pin, through which the device is fixed on a stationary object.

Manual drum wire rope winch

Manual drum belt winch

The work of MTM is as follows. The cable is threaded through the entire body of the winch, it is located between the clamping blocks, which, when the lever moves, act alternately. When the lever moves in one direction, one block is clamped and shifted back, the second block is unclenched and moves forward - as a result, the rope is stretched and pulls the load. When the lever moves back, the blocks change roles - as a result, the cable is always fixed by one of the blocks and pulled through the winch.

The advantage of MTM is that it can be used with a cable of any length, as long as it has a suitable cross-section.

Hand winches develop a force of 0.45 to 4 tons, drum winches are equipped with cables or tapes from 1.2 to 9 meters long, MTM can have cables up to 20 meters or more in length. Lever winches, as a rule, are additionally equipped with a power polyspast - an additional hook with a block that doubles the force applied to the load. The bulk of modern hand winches are equipped with steel hooks with spring-loaded locks, which provide not only fastening of the load, but also prevent the slipping of another cable or rope when performing lifting and transport operations.

How to choose, install and use a hand winch

When choosing a winch, it is necessary to take into account the conditions of its operation and the maximum weight of the goods being moved. For use on cars and SUVs, it is quite enough to have winches with a carrying capacity of up to two tons, for heavier vehicles - up to four tons. Winches with a carrying capacity of 0.45-1.2 tons can be used to move relatively small loads during the installation of various structures, on construction sites or retail spaces.

For cars and those situations when the winch has to be moved from place to place or choose the most convenient place for fastening, it is better to use mobile lever devices. And if there is a special place for mounting the winch, then you should give preference to a device with a gear or worm drive. In those cases when it is necessary to use cables of great length, it is better to resort to the help of MTM.

An interesting choice can be winches with polyspast: small loads can be moved without a polyspast at high speed, and large loads with polyspast, but at a reduced speed. You can also purchase additional hooks and cables, which will allow you to perform various operations.

Manual drum winch with worm drive

Hand winches should be operated taking into account the instructions and general recommendations for loading and unloading and lifting and transport operations. When using lever winches and MTM, they should be securely fixed on stationary objects or structures. During the operation of the winch, people should keep a safe distance from the cable and the load to avoid injury. You also need to avoid overloading the winch.

The correct selection and operation of the winch is a guarantee of efficient and safe performance of work in any conditions.

Post time: Jul-12-2023