For the normal operation of many car systems, pipelines that are resistant to oils, gasoline and other aggressive environments are needed. Oil-and-gasoline-resistant (MBS) hoses, hoses and tubes are used as such pipelines - read about these products, their types, design and characteristics in this article.

What is an oil-resistant hose?

Oil-and-gasoline-resistant hose (MBS hose, MBS hose) is a flexible pipeline designed to supply (supply, pump) gasoline, diesel fuel, oils, brake fluids and other petroleum products, as well as coolants, weak acid solutions and other weakly aggressive media.

MBS hoses are used for hermetic connection of components in fuel, oil, brake and other systems of vehicles, in hydraulic systems of low and high pressure production equipment, for pumping petroleum products between tanks and various equipment, etc. Unlike rigid metal pipelines, hoses allow the displacement of system components relative to each other, they resist deformations and negative effects well. All this led to the widespread use of MBS hoses in various branches of technology, industry, etc.

Types and characteristics of MBS hoses

MBS hoses (hoses) are classified according to the main material of manufacture, purpose and applicability, and characteristics.

According to the material of manufacture, hoses are:

• Rubber - the inner and outer layers of the hose (sleeves) are made of various types of rubber that are resistant to certain liquids and gases;

• PVC – the hose is made of various brands of polyvinyl chloride and other polymers that are resistant to various aggressive environments.

According to the purpose, MBS hoses are divided into three groups:

• Pressure - designed to work under increased pressure (from atmospheric and above), measures have been taken in their design to prevent deformations and ruptures of the walls by the injected liquid;

• Suction - designed to operate under reduced pressure (below atmospheric), measures have been taken in their design to prevent compression of the walls under the action of vacuum (to maintain a constant internal cross-section);

• Universal pressure-suction.

According to applicability, hoses can be divided into several groups:

• For use in everyday life, auto repair shops and in other situations without embedding the hose in vehicles or other equipment;

• For vehicle fuel systems;

• For braking systems of vehicles with the use of working fluid based on mineral and synthetic oils;

• For hydraulic systems of vehicles, automotive machinery, agricultural machinery, industrial and other equipment;

• For refueling equipment (for pumping fuels and oils, supplying fuels to the consumer, etc.).

Finally, hoses are divided into two types in relation to static electricity:

• Conventional hoses;

• Grounded hoses to divert static electricity.

In the design of hoses of the second type, a copper strip is provided, which plays the role of grounding. These MBS hoses are used on refueling machinery and equipment, on industrial equipment, etc.

Of the characteristics of the SBS barriers, it should be noted:

• Operating pressure - for suction - 0.09 MPa (0.9 atmospheres), for discharge - the standard range of 0.1, 0.16, 0.25, 0.4, 0.63, 1.0, 1.6, 2.5, 4, 6.3 and 10 MPa (from 1 to 100 atmospheres);

• Inner diameter – from 3 to 25 mm (PVC hoses) and from 4 to 100 mm (rubber hoses);

• Outer diameter – depends on the thickness of the walls, the type of braid, the presence of reinforcement, etc. As a rule, the outer diameter is 1.5-3 times larger than the inner diameter;

• Operating temperature range.

Separately, it must be said about the last parameter. Today, MBS hoses are produced for three climatic zones, they differ in the maximum permissible negative temperatures:

• For temperate climates - up to -35 ° C;

• For tropical climates - up to -20 ° C;

• For cold climates - up to -50 ° C.

The maximum positive temperature for all hoses is the same - up to + 70 ° C for fuels (gasoline, kerosene, diesel fuel) and up to + 100 ° C for oils.

MBS hose design

PVC hoses (tubes) are arranged most simply. In the simplest case, this is a hose, in the walls of which there is a textile or wire braid. There are also multilayer varieties of PVC tubes - they have an inner layer that is highly resistant to fuels, oils and other liquids. Reinforcement can be located in the outer layer or between layers.

Rubber hoses by design are divided into several groups:

• Unreinforced with thread reinforcement (GOST 10362-76);

• Unreinforced with thread / textile reinforcement and textile frame (GOST 18698-79);

• Reinforced of the same types (GOST 5398-76).

Unreinforced hoses with thread reinforcement are most simply arranged, they are a three-layer structure:

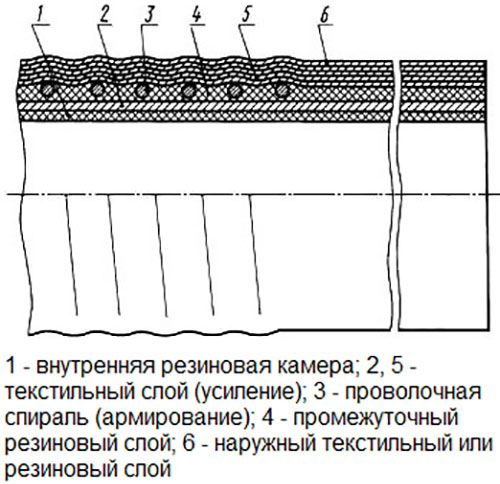

The structure of the reinforced rubber hose MBS

1.The inner layer is rubber that is resistant to oils, fuels and other liquids;

2.Thread / textile reinforcement - braid made of synthetic, cotton or combined threads / fabrics, can be performed in 1-6 layers;

3.The outer layer is rubber that is resistant to negative environmental influences, oils and fuels, various chemicals, etc.

Hoses with a textile frame contain an additional outer layer - a textile braid made of synthetic, cotton or combined fabric. The frame is wound on a hose in several layers. Often this type of product is called durite or hoses with durite braiding.

In reinforced hoses, an intermediate rubber layer is added, in which steel or copper wire (according to domestic standards) or a thin metal mesh is placed. Reinforcement can consist of one or two layers, but there are special sleeves with reinforced multi-layer reinforcement. A copper ground strip can be located in the same layer of the hose.

Some types of rubber hoses are equipped with end fittings on one or both sides. Such hoses, as a rule, are designed for installation in certain components, assemblies and systems of cars and other equipment, they are cut to the desired size and have the necessary characteristics.

The characteristics, nomenclature and production of rubber hoses MBS are regulated by the above and some other standards. Similar PVC hoses do not have a single standard, they are produced in accordance with different specifications.

Issues of selection and operation of MBS hoses

A variety of oil-resistant hoses

When choosing oil-resistant hoses, it is necessary to take into account their future purpose and the conditions in which these products will be operated.

For private use for the purpose of pumping fuel or oils, an inexpensive PVC hose is quite enough - it is lightweight, easy to store and easy to use (transparent walls allow you to determine the presence of fluid flow, etc.).

For the repair of fuel, lubrication, braking and other systems in which the increased pressure of the working medium is maintained, MBS rubber hoses should be used. When buying, it is necessary to choose the right inner diameter and characteristics - working pressure and temperature range. In this case, it is additionally necessary to take care of the clamps and end fittings for mounting the hose.

Often, for the repair of some systems, components and assemblies, hoses with already installed end fittings are sold - this is the optimal solution that saves time and money (since there is no need to cut the hose to length and install fittings), and provides the greatest reliability of the system.

For industrial and other special applications, it is necessary to choose MBS hoses with certain characteristics, including the possibility of grounding, large-diameter products, hoses for a certain type of liquids, etc.

End fittings of MBS hoses

To make the right choice of hose, you need to pay attention to its marking. In accordance with the standards, the marking includes an indication of the inner and outer diameter, working pressure, climatic modification and GOST, which corresponds to this product. For example, the marking "Hose 20x30-1 GOST 10362-76" means that the hose has an inner diameter of 20 mm, an outer diameter of 30 mm, a working pressure of 1 MPa and is designed to work in temperate and tropical climates. The presence of the letters "HL" indicates the possibility of using the hose in cold climates. Oil-and-gasoline-resistant hoses in accordance with GOST 18698-79 are marked with the type "Sleeve B (I) -10-50-64-T" - where "B (I)" means the applicability of the product for working with gasoline and oils, the first digit is the working pressure in the atmospheres, the last two digits are the inner and outer diameters, the last letter is the climatic modification ("T" - for a tropical climate, "U" - temperate, "HL" - cold). Hoses according to GOST 5398-76 have a similar marking of the type "Hose B-2-25-10 GOST 5398-76", where "B-2" is the applicability of the product for working with fuels and oils, "25" is the inner diameter (the outer diameter is not indicated), and 10 is the working pressure in atmospheres. It also indicates the climatic version (for temperate climates - not marked, for tropical - "T", for cold - "HL").

Knowing this, you can easily choose the necessary hose, and confidently solve the tasks.

Post time: Aug-22-2023