Every modern car is equipped with several brake systems, including parking, or "handbrake". The brake mechanisms of the handbrake are driven by flexible steel cables - read all about these parts, their existing types and designs, as well as their selection and replacement, in the article.

What is a parking brake cable?

Parking brake cable (handbrake cable, handbrake cable) - an element of the parking brake drive of wheeled vehicles; A metal twisted cable in a protective sheath that connects the parking brake drive lever to the brake pads and intermediate parts of the drive.

Wheeled vehicles equipped with a hydraulically operated braking system use a mechanical parking brake with direct brake pads from a lever installed in the cab/passenger compartment. The drive of the pads is built on the basis of flexible elements - cables that perform the functions of rods.

The parking brake cable performs several functions:

● Transmission of force from the parking brake lever to the brake pads of the rear axle wheels (in passenger cars) and to the handbrake pads on the propeller shaft (in some trucks);

● Compensation for deformations of the frame, car body elements and suspension parts, as a result of which the relative position of the pads and the lever may change - this is realized due to the flexibility of the cable (cables);

● The general simplification of the design of the parking brake - when using cables, there is no need to use rigid rods with hinges and numerous fasteners.

Handbrake cables play a key role in the safety of the vehicle during short and long parking lots, and make a significant contribution to the overall level of safety on the roads. Any malfunction of the cable can result in an emergency, so this part must be replaced as soon as possible. But before buying a handbrake cable, you need to understand the types, design and features of these components.

Types, design and features of parking brake cables

Currently, cars use a parking brake with three main types of drive:

● With one cable and stiff pull;

● With two cables and stiff traction;

● With three cables.

The simplest device has a drive with a single cable: it uses a rigid central rod, which is connected to a lever and a steel guide that holds the cable threaded through it; The cable is connected by its ends to the brake pad drives on the right and left wheels. Here, one cable is divided in two, each of its halves works on its own wheel, and the force from the lever is transmitted using a threaded steel rod on which the guide is held. Such a system is easy to operate and adjust, but it has relatively low reliability, since wear or breakage of the cable leads to a complete disruption of the functioning of the parking brake.

Many trucks also use a parking brake with a single cable - it is used to bring the pads on the brake drum mounted on the propeller shaft together. In such a system, the cable is directly connected to the handbrake lever without the use of intermediate rods.

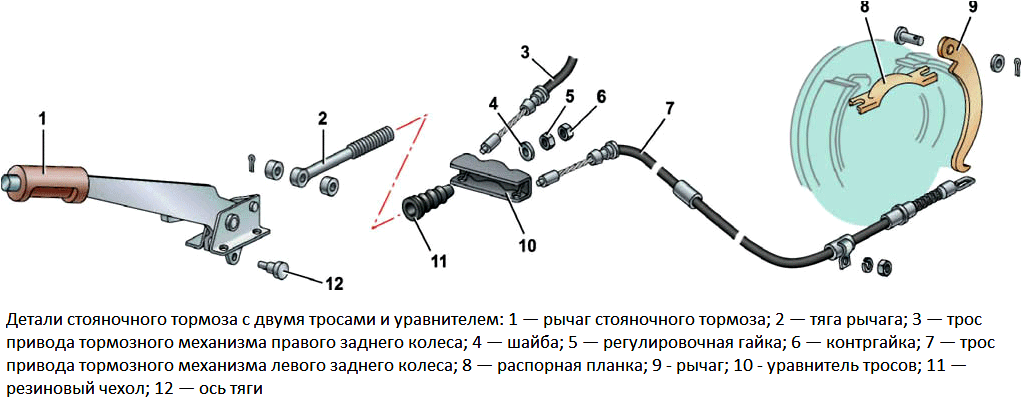

Parts of the parking brake drive with two cables and a cable equalizer

A more complex device has a drive with two cables: it uses two separate cables connected to the so-called equalizer or compensator, which, in turn, is located on a rigid rod. Due to the presence of two independent cables, the performance of the parking brake is maintained when one of them is worn or ruptured - the force on the second wheel is transmitted by the second whole cable. Such a drive is somewhat more complicated than the previous one, but it has higher reliability, so today it is the most widely used.

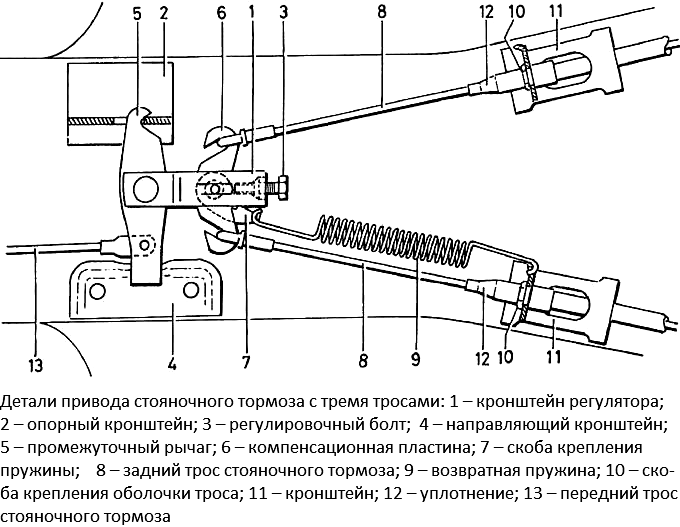

In drives of the third type, the rigid rod is replaced by a third short cable - it connects the parking brake lever with the equalizer / compensator of the rear cables. Such systems have great flexibility in terms of adjustments and work well even with significant displacements of drive parts relative to each other (for example, with a large and uneven load of the car, when parking the car at a slope, when one of the rear wheels hits a hill or recess, etc.). Therefore, the handbrake drive with three cables today is also widely used on cars of various types and classes.

A separate group of drives consists of systems with two cables of different lengths. One cable is connected directly to the drive lever and provides a drive for the pads of one of the wheels (most often the left one). The second cable of shorter length is connected to the first at some distance from the lever, usually it is laid along the bridge beam, which ensures high reliability of the entire structure (so the cable is protected from negative influences, shocks and bends). The connection of the cables is carried out using an equalizer (compensator) with the possibility of adjustment.

Three-cable parking brake drive parts

All parking brake cables have a fundamentally identical device, differing only in some details. The basis of the structure is a steel twisted cable of small diameter (within 2-3 mm), placed in a protective sheath. Inside, the shell is filled with grease, which prevents corrosion and jamming of the cable. At the ends of the cable, the tips are rigidly fixed for connection with the drive parts - the lever, equalizer, brake pad drive. The tips can have a different design:

● Taw;

● Cylinders;

●Hinges of various shapes and sizes;

● U-shaped tips (forks).

The sheath of the cable occupies its entire length, with the exception of a few centimeters on the side of the tips. The shell can have a different design:

● Polymer (regular or reinforced) single-layer sheath along the entire length of the cable;

● Armor (spring) shell at the tips of the cable, which are in contact with the surrounding parts of the suspension and body, and therefore subject to significant wear;

● Rubber corrugations (anthers) at the tips of the cable (on one or both sides), which protect the cable from dust and dirt, and also prevent the leakage of grease.

At both ends of the shell, metal bushings with different designs are fixed:

● With an external thread and two nuts - usually such a sleeve is located on the side of attaching the cable to the equalizer (more precisely, to the bracket that prevents the shell from shifting), but there are cables with threaded bushings on both sides;

● With internal thread - such bushings are most often used on truck parking brake cables;

● With a thrust plate or bracket - such a sleeve is located on the side of attaching the cable to the wheel brake shield.

In this case, the bushings can be straight or curved, which is due to the design features of the parking brake of the car.

Parking brake cables complete with equalizer

Additional (reinforced) polymer bushings, clamps and brackets can also be located on the cable sheath - these are the mounting elements necessary for the correct location of the cable and its fastening on the elements of the body or frame of the vehicle.

As a rule, the length and other characteristics of the cable are indicated on its label or in the relevant reference books - this information helps to choose a new cable when the old one wears out.

How to choose and replace the parking brake cable

Parking brake cables are subjected to significant loads, so they wear out, stretch and lose their strength over time. During routine maintenance, it is recommended to inspect the cables and, if necessary, adjust their tension force - usually this is done with a nut on a rigid rod or equalizer. If such an adjustment does not ensure the normal operation of the handbrake (the cable is excessively stretched and does not provide a reliable fit of the pads), then the cable (cables) must be replaced.

The selection of cables must be carried out in accordance with the model and year of manufacture of the vehicle - the new cable must have the same catalog number as the old one. If the desired cable is not available, then you can try to choose a cable of a different type in length, design and type of tips. You can also pick up analogues from other cars, components for the production of which are supplied by the same manufacturers.

If the handbrake drive has two rear cables, and only one of them is faulty, then it is recommended to change the entire pair at once - this will insure against an imminent breakdown of the second cable. Especially for such situations, many manufacturers offer sets of cables and all the necessary intermediate parts.

Replacement of handbrake cables must be carried out in accordance with the instructions for repair and maintenance of this particular car. As a rule, this work is reduced to loosening and dismantling the equalizer / compensator, after which you can remove the cable by unscrewing the nuts from the fasteners and removing the tips from the holders on both sides. The installation of the new cable is carried out in reverse order, after which adjustment is made in order to ensure the desired tension of the cables. When performing work, it is necessary to ensure the stability and immobility of the car with the help of shoes or other means. Subsequently, it is necessary to monitor the condition of the cables and periodically adjust their tension.

With the right choice and replacement of cables, the car's parking brake system will work reliably and efficiently in any parking lot.

Post time: Jul-26-2023