Mechanical and electromechanical speedometers, as well as gearbox-mounted speed sensors for cars and tractors, have a worm drive implemented on a pair of gears. Read about what a speedometer drive gear is, what types it is, how it works and works in this article.

The purpose and place of the speedometer drive gear in the car

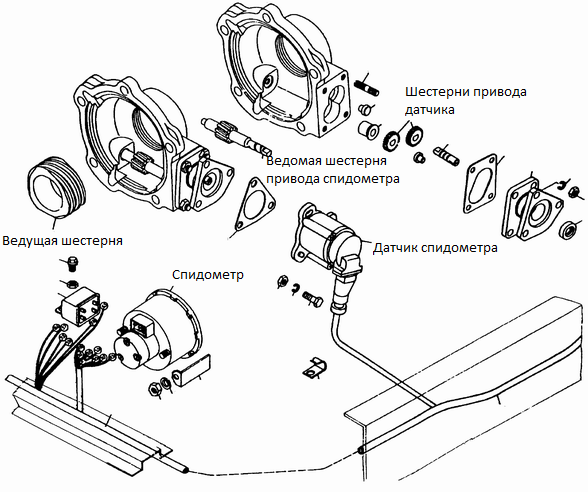

In modern vehicles and automotive technology, two methods of measuring speed are used - measuring the angular velocity of rotation of the secondary shaft of the gearbox and measuring the angular velocity of rotation of the drive wheels. In the first case, mechanical and electromechanical sensors with direct drive from the shaft are used, and in the second case, non-contact sensors, usually combined with ABS sensors. Despite the widespread use of non-contact sensors, conventional speedometer drives are still relevant - they will be discussed in the future.

The mechanical drive of the speedometer can have a different arrangement:

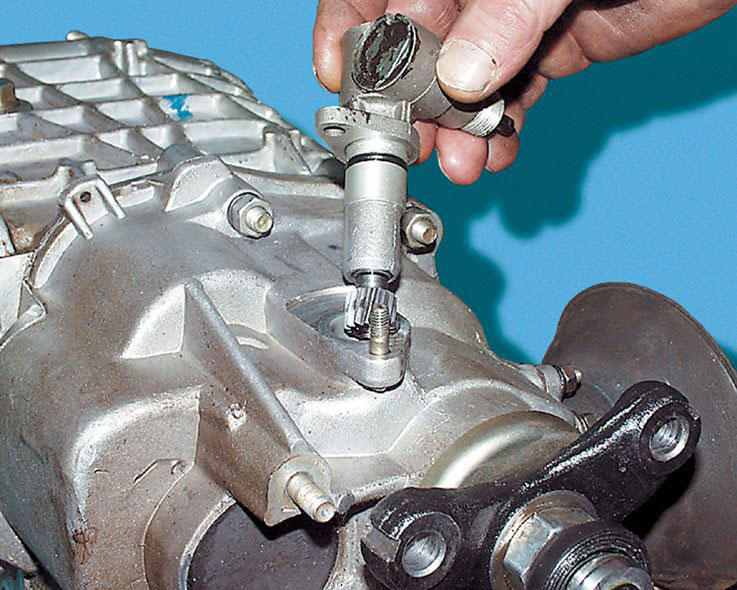

- In the gearbox (gearbox);

- In the transfer case (RK).

In motorcycles, scooters and other motorcycles, the speedometer drive is most often installed in the wheel.

Regardless of position and type, the speedometer drive is implemented on a worm pair that receives torque from the secondary shaft of the gearbox or RK. The choice of worm gear is not accidental - it provides a change in the torque flow by 90 ° (perpendicular to the axis of the secondary shaft) and the ability to mount the speedometer sensor in the wall of the gearbox crankcase. Also, the worm gear for the speedometer drive with small gear sizes has a higher gear ratio and better reliability than bevel gear transmission.

The mechanical drive of the speedometer can have a different arrangement:

- In the gearbox (gearbox);

- In the transfer case (RK).

In motorcycles, scooters and other motorcycles, the speedometer drive is most often installed in the wheel.

Regardless of position and type, the speedometer drive is implemented on a worm pair that receives torque from the secondary shaft of the gearbox or RK. The choice of worm gear is not accidental - it provides a change in the torque flow by 90 ° (perpendicular to the axis of the secondary shaft) and the ability to mount the speedometer sensor in the wall of the gearbox crankcase. Also, the worm gear for the speedometer drive with small gear sizes has a higher gear ratio and better reliability than bevel gear transmission.

Types and design of speedometer drive gears

The speedometer drive gears are divided into two types:

- Drive gear (worm);

- Driven gear.

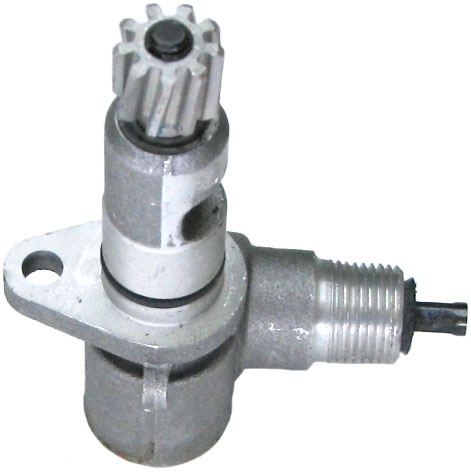

The drive gear - or worm - is always made as a separate part, which is mounted on the shaft by means of a key, retaining ring or otherwise. The worm has a large diameter and a small number of teeth.

The driven gear can also be made as a separate part, or manufactured at the same time as its own shaft. This gear is always helical gear, with the number of teeth ranging from 11 (for cars) to 24 (for trucks).

The speedometer drive gears are divided into two types:

- Drive gear (worm);

- Driven gear.

The drive gear - or worm - is always made as a separate part, which is mounted on the shaft by means of a key, retaining ring or otherwise. The worm has a large diameter and a small number of teeth.

The driven gear can also be made as a separate part, or manufactured at the same time as its own shaft. This gear is always helical gear, with the number of teeth ranging from 11 (for cars) to 24 (for trucks).

Post time: Aug-24-2023