Each engine has timing drives and mounted units built on a belt or chain. For normal operation of the drive, the belt and chain must have a certain tension - this is achieved with the help of tensioning devices, the types, design and correct choice of which are described in this article.

What is a tensioning device?

Tension device (belt tensioner, chain) - an auxiliary device for the drive of the gas distribution mechanism (timing) and drives of units of piston internal combustion engines; A mechanism that sets and maintains the optimal tension of the drive belt or chain.

The tensioning device performs several functions:

• Installation and adjustment of the tension force of the drive belt/chain;

• Compensation of belt/chain tension that changes due to wear of drive parts and changes in environmental conditions (stretching and compression of the belt/chain under fluctuations in temperature and humidity, under the influence of vibration loads, etc.);

• Reducing the vibrations of the belt or chain (especially their long branches);

• Prevent the belt or chain from slipping off pulleys and gears.

Although tensioning devices are auxiliary mechanisms of the engine, they play an important role - they ensure the normal functioning of timing drives and mounted units, and hence the entire power unit in constantly changing conditions. Therefore, in the event of a malfunction, these devices must be repaired or replaced. To make the right choice of a new tensioner, it is necessary to understand the range of these mechanisms presented today, their design and features.

Types and applicability of tensioning devices

Tensioning devices are divided into groups according to their purpose, applicability to a particular type of drive, principle of operation, method of tension adjustment and additional functionality.

According to the purpose, tensioners are of two main types:

• For timing drives;

• For drives of mounted units of the power unit.

In the first case, the device provides the necessary tension of the chain or timing belt of the engine, in the second - the tension of the belt of the general drive of the units or belts of individual units (generator, water pump and fan, air compressor and others). Several tensioners of different design and purpose can be installed on one engine at once.

According to applicability, tensioning devices are divided into three groups:

• For chain drives;

• For drives on a conventional V-belt;

• For V-ribbed drives.

Tensioners for different drives differ in the design of the main element - the pulley. In devices for chain drives, a gear wheel (sprocket) is used, in V-belt transmissions - a V-pulley, in polyclin drives - a corresponding V-ribbed or smooth pulley (depending on the method of installing the device relative to the belt - from the side of the streams or from the back smooth side).

According to the principle of operation, tensioning devices are divided into three types:

• Tensioners with rigid pulley installation;

• Spring tensioners;

• Hydraulic tensioners.

Each of the types of tensioning devices has its own characteristics, their varieties and design are described below.

According to the method of adjusting the tension force, the devices are:

• Manual;

• Automatic.

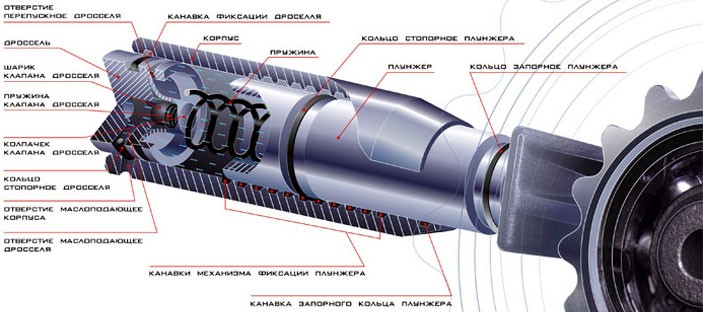

The design of the hydraulic cylinder of the timing chain tensioning device

In devices of the first type, the tension force is set (adjusted) manually during maintenance or if necessary. The adjusted tensioner is always in one position and cannot compensate for the tension force of the belt/chain. The second type of device automatically changes its position depending on the current conditions, so the tension force of the belt is always constant.

Finally, tensioning devices can be combined with other devices and perform additional functions - with chain dampers, limiters, etc. Usually, these parts are sold as part of repair kits for routine maintenance of timing drives or units, or for engine repair.

Design and principle of operation of tensioning devices with rigid pulley installation

These tensioners include three types of devices:

• Lever;

• Slide;

• Eccentric.

The lever tensioner consists of a bracket that is rigidly mounted on the engine and a movable lever with a pulley mounted on it. The lever is held on the bracket by two bolts, and one of them is located in the arcuate groove - it is the presence of the groove that allows you to adjust the position of the lever and, accordingly, the tension force of the belt.

Slide-type tensioning devices are widely used: in them the pulley is not mounted on a lever, but in a straight groove of the bracket, along which a long screw (bolt) is passed. By rotating the screw, you can move the pulley along the groove, thereby changing the tension force of the belt. When the required tension force is established, the screw is countered with a nut, ensuring the immobility of the pulley.

On passenger cars, eccentric tensioning devices are most often used. Structurally, this tensioner consists of a roller with an eccentric hub fixed on the engine block or bracket. The tension force is changed by turning the roller around the axis and fixing it in the selected position with a bolt.

All the described tensioners are manually adjustable devices that have a significant drawback - they cannot compensate for the change in the tension force of the belt. This disadvantage is eliminated in spring and hydraulic tensioning devices.

Design and principle of operation of spring tensioning devices

There are two types of spring tensioners:

• With a compression spring;

• With a torsional spring.

In devices of the first type, automatic adjustment of the belt tension is performed by a conventional twisted spring, which presses the bracket with the roller / sprocket to the belt / chain. In devices of the second type, this work is performed by a wide twisted spring, twisted with a certain force.

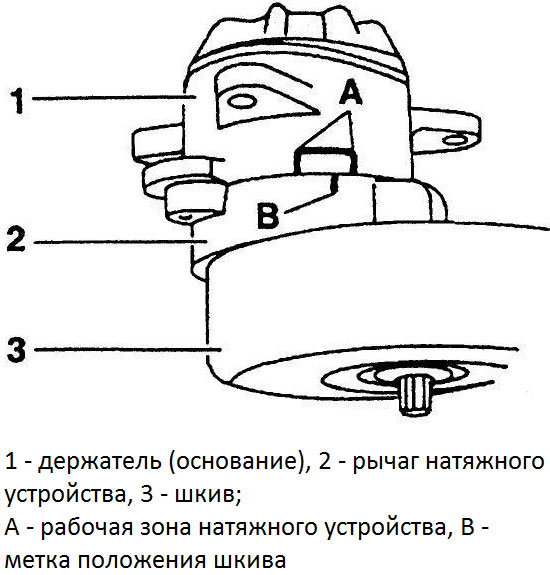

Torsional spring tensioners are the most widely used today - they are compact, simple and reliable. Such a device consists of a lever with a pulley and a base (holder) with a spring, for convenient installation, the spring on the new tensioning device is already compressed with the necessary force and fixed with a check.

Tensioning device with torsion spring

As a rule, spring tensioning devices are used in belt (V-and V-ribbed) drives of mounted units, as well as in timing drives of passenger car engines with timing belts.

Design and principle of operation of hydraulic tensioning devices

The basis of this type of tensioners is a hydraulic cylinder that presses the pulley/sprocket to the belt/chain. The cylinder has two communicating cavities, separated by a movable plunger, which is connected to a pulley / sprocket with the help of a rod (or rather, to the lever of the tensioning device with a pulley / sprocket mounted on it). Also in the cylinder there are several valves for bypassing the working fluid. In the middle position of the plunger, the cylinder provides the necessary belt / chain tension and does not affect the operation of the drive in any way. When the tension of the belt / drive changes, the plunger changes its position, the working fluid flows from one cavity to another, ensuring the normal tension of the belt in the new position. Various types of engine oils are used as a working fluid.

The hydraulic cylinder can be mounted on a bracket or on an engine, in timing chain drives, two cylinders are usually used at once, each of which works on its own sprocket. The new cylinders have a preset tension force, their rods are fixed in the desired position with a check.

Issues of selection, maintenance and repair of tensioning devices

During the operation of the vehicle, tensioning devices wear out intensively and lose their qualities, so they need to be regularly checked and replaced. Only those tensioners recommended by the engine manufacturer should be selected for replacement - otherwise the device cannot be installed, or it will not provide the necessary tension of the belt or chain.

Tensioning devices of belt drives of mounted units are the most durable and can serve for many years, they should be changed with significant wear or breakdowns. The new tensioner should be installed and adjusted in accordance with the vehicle's operating instructions. If the device is with a rigid pulley fixation, then it should be adjusted by changing the position of the lever or using a screw. If the device is spring, then it must first be mounted, and then remove the check - the pulley itself will take the working position. In this case, it is necessary to ensure that the mark on the lever falls into the zone on the base of the device, otherwise you should change the belt or check the serviceability of the tensioner.

Correct installation of the tensioning device according to the marks

The tensioning devices of timing chain drives are usually changed complete with the chain, dampers and other components. Replacement of these parts should be carried out in strict accordance with the instructions of the instructions. Tensioners of this type do not require adjustment, they must be installed and then removed from the check - the sprocket will take the working position and ensure the correct tension of the chain.

With the right choice and replacement of tensioners, timing drives and units will work reliably in any operating conditions.

Post time: Aug-05-2023