The components and assemblies of the steering systems of vehicles are connected by means of ball joints, the main element of which are fingers of a special shape. Read about what tie rod pins are, what types they are, how they are arranged and what functions they perform in ball joints - read the article.

What is a tie rod pin?

The tie rod pin is a part of the ball joint of the steering gear of wheeled vehicles. Steel rod with ball head and threaded tip for mounting, playing the role of the axis of the hinge and the main fastener.

The finger connects the rods and other parts of the steering gear, forming a ball joint. The presence of a hinge of this type ensures the mobility of the mating parts of the steering gear in both the longitudinal and transverse planes. Thus, the normal operation of the drive is achieved regardless of the position of the wheels (when deviating from the centerline when cornering, when hitting uneven roads, etc.), their adjustment (alignment), vehicle load, deformations of the wheel beam, frame and other parts that occur during the movement of the car, etc.

Types and design of tie rod pins

Fingers can be divided into types according to purpose and place of installation, as well as some design features.

According to the purpose and place of installation, the fingers are:

• Steering rod pins - connect the parts of the steering trapezoid (longitudinal, transverse rods and steering knuckle levers);

• Steering bipod pin - connects the steering bipod and the longitudinal bipod rod / bipod lever.

The steering gear uses 4 to 6 ball joints, one of which connects the steering bipod to the longitudinal tie rod (in cars with a steering rack, this part is missing), and the rest are tie rods, steering knuckle levers (swing arms) and pendulum arms (if present in the drive). Ball joints and the fingers used in them can be interchangeable, or performed for installation in a specific hinge. For example, in automobiles, separate pins can be used for the bipod hinge and longitudinal rod, the joints of the transverse rod connection with the swing arm, etc.

Regardless of the type and purpose, the tie rod pins have the same design in principle. This is a steel turned part, which is conditionally divided into three parts:

- Ball head - a tip in the form of a sphere or hemisphere with a "collar";

- The body of the finger is the middle part, made on a cone to connect with another rod;

- Thread - a tip with a thread to fix the hinge.

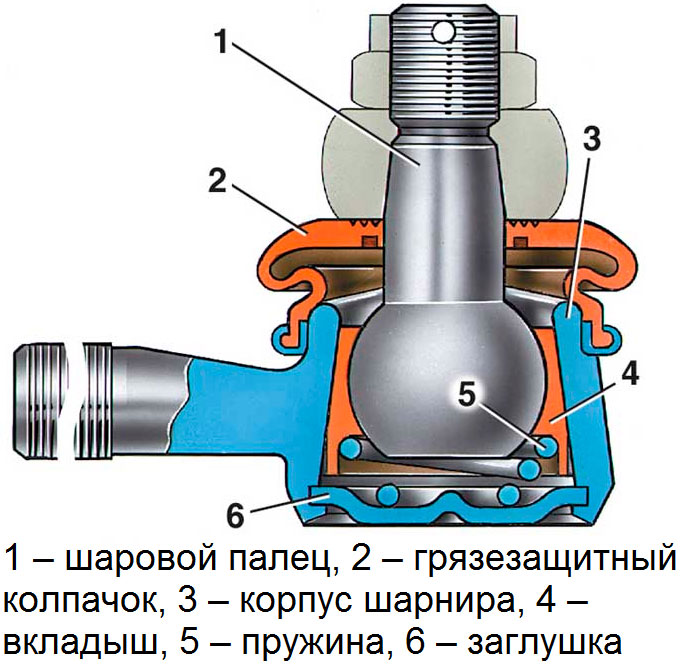

The finger is part of the ball joint, which is made in the form of an independent part - the tip (or head) of the tie rod. The tip plays the role of the hinge body, inside which the finger is located. A liner is installed inside the cylindrical or conical cup of the tip, it covers the spherical head of the finger, ensuring its deflection in all planes (within 15-25 degrees). Liners can be one-piece plastic (Teflon or other wear-resistant polymers, used on cars) or collapsible metal (consist of two halves, used on trucks). Collapsible inserts can be vertical - cover the head on the sides, and horizontal - one liner is located under the spherical head of the finger, the second liner is made in the form of a ring and is located above the head.

Typical design of the tie rod ball joint of passenger cars

At the bottom, the glass is closed with a removable or non-removable lid, a spring is installed between the lid and the liner, which ensures reliable contact between the liner and the spherical finger head. From above, the hinge body is closed with a protective cap (anther). On the protruding conical part of the finger, the counterpart of the rod, bipod or lever is put on, fastening is carried out with a nut. For reliable installation, slotted (crown) nuts are usually used, fixed with a cotter pin (in this case, a transverse hole is provided in the threaded part of the pin).

All ball joints of tie rods have the described design, the differences are only in minor details (types of nuts, configuration of pins and their location, design of liners, types of springs, etc.) and dimensions.

The right choice and repair of tie rod pins

Over time, the spherical head and tapered part of the pin, as well as the liners and other parts of the hinge, wear out. This leads to backlash and runout in the steering gear, which translates into a decrease in the comfort and quality of steering, and ultimately in a decrease in the safety of the vehicle. If there are signs of wear or breakage, the tie rod pins or ball joint assemblies must be replaced.

Repairs can be performed in several ways:

• Replace only the finger;

• Replace the pin and mating parts (liners, spring, boot, nut and cotter pin);

• Replace the tie rod tip assembly with hinge.

The best solution is to replace the pin with the mating parts, since all new components have no backlash and ensure the normal connection of the tie rods and other components. In this case, it is necessary to use a special device to squeeze out the old finger and install a new one. However, this solution is not always suitable - on some passenger cars, the pin cannot be removed from the hinge, it changes only in the assembly.

Replacement of the tie rod tip assembly with a hinge is needed only in case of serious malfunctions of this unit - deformations, corrosion, destruction. In this case, the old tip is removed, and a new one is installed in its place. When replacing the pins or tie rod tips, it is necessary to ensure that the nut is securely fixed (with a cotter pin or in another prescribed way), otherwise it may turn away, which will lead to a malfunction of the steering or to a complete loss of controllability of the vehicle.

The new part does not need special maintenance and care, it is only necessary to periodically inspect the hinges and, if signs of wear or breakage appear, replace them. For replacement, it is necessary to select the fingers or tips recommended by the vehicle manufacturer. These parts must be suitable in size and design (provide the necessary angle of deflection of the finger), otherwise the steering will not work correctly. With the right choice of tie rod pin, the steering gear will be repaired in compliance with the standards, and the car will again receive comfortable and safe control.

Post time: Aug-21-2023