Replacing the valves of an internal combustion engine is hampered by the need to remove crackers - special valve dryers are used for this operation. Read all about this tool, its existing types, design and principle of operation, as well as its choice and application, in this article

What is a valve dryer

The valve dryer is a specialized device for dismantling and installing valves of the gas distribution mechanism of internal combustion engines.

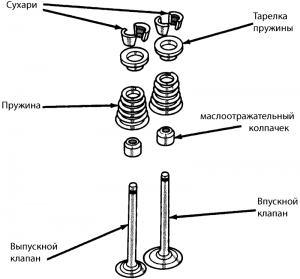

In modern internal combustion engines, the valves are fixed in the working position with the help of special parts - crackers. These parts are most often made in the form of steel half-rings with collars, which, due to the peculiarities of the installation, jam the valve, and with it the spring and other parts of the valve mechanism. Crackers with their collars enter the annular recess in the upper part of the valve stem and are placed in the central recess of the spring plate, the jamming of the parts is ensured by the force of the spring. Such installation of valves is extremely simple and reliable, but it makes it difficult to disassemble the mechanism - to remove crackers, it is necessary to compress the spring, which may require the application of a force of 20-30 kg or more. To perform this work, special devices have been developed - valve dryers.

With the help of a valve dryer, two operations are performed:

● Dismantling the valve by removing breadcrumbs;

● Installation of the valve by installing breadcrumbs.

Today, there is a wide variety of crackers that are different in design and applicability - for the right choice, you need to understand the classification and design features of this tool.

typical valve installation scheme

Types and design of valve dryers

Regardless of the design, the work of all crackers is based on one principle: the tool in one way or another compresses the spring (springs) of the valve, freeing the crackers, or opening access to their installation. The tools differ in the method of compression of the spring, as well as the method of installation on the head and the possibility of using on heads with different arrangement of valves, spark plugs (in gasoline engines) and camshafts.

According to the method of compression of the spring, dryers are divided into the following types:

● clamping;

● Lever;

● Screw.

The clamp dryer is a device in the form of a C-shaped clamp, on one side of which there is a thrust screw for the valve disc, and on the other side a thrust sleeve is installed for the valve spring disc. For ease of installation and removal, the device may have a lever on one or both sides. A dehumidifier of this type can only be used on the removed cylinder head, its thrust screw is installed on the side of the combustion chamber, resting against the valve plate, and the sleeve rests against the spring plate, when screwing in the screw and / or bushing, the spring is compressed, releasing the crackers.

Clamp-type valve dehumidifier

Lever Valve dehumidifier

Lever crackers have a simpler design, they are designed to perform work without removing the cylinder head. This tool can be divided into several types according to the method of installation and application:

● Lever without hinges;

● Lever with hinges;

● Lever for overhead motors with fulcrums at the lower coils of the spring;

● Lever universal.

Lever crackers without hinges are arranged most simply: this is a rod with a handle, at the end of which there is a working part in the form of a double-sided fork. Such a tool is fixed with a narrow fork using a screw screwed into the cylinder head next to the valve, and rests on the valve plate with a wide fork - when the lever is pressed, the spring is compressed, releasing the crackers. Such tools are used to repair the engines of Volga cars of GAZ-24-10 models and later.

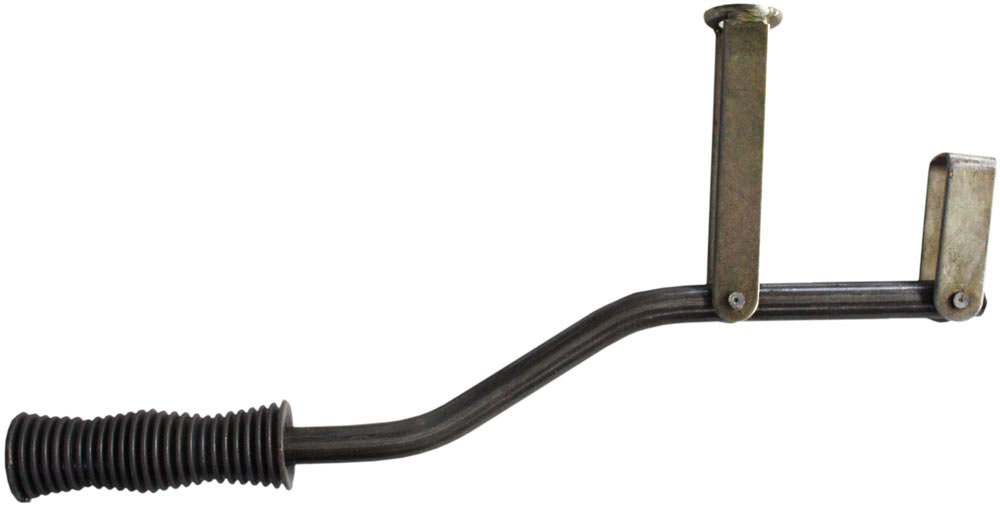

Lever crackers with hinges are more complex, but they are more versatile and easy to use. Such a tool is made in the form of a lever with a handle, at the end of which there is a hinged bracket for the stop, and closer to the center there is a hinged sleeve for the emphasis on the spring plate. The cracker bracket is fixed to the cylinder head with a bolt, and the sleeve rests on the spring plate - when the lever is pressed, the spring is compressed, ensuring the release of breadcrumbs. A tool of this type is widely used for servicing VAZ, GAZelle and many foreign-made vehicles.

Lever dryers for engines with an overhead camshaft have a different device that makes it possible to use the tool in a confined space. Usually, such a device is made in the form of a grip with two legs, in the center of which there is a thrust sleeve for a spring plate with its own lever. The tool is installed in such a way that the legs rest against the lower ends of the spring, as a result of which, when you press the lever, the spring compresses and releases the breadcrumbs. True, when working with this tool, it is necessary to apply considerable force to the lever, otherwise the paws can raise the lower coils of the spring and drying will not occur.

Universal lever crackers are a large group of tools designed to work with various engines:

● With conventional in-line engines with a lower camshaft;

● With engines with an overhead shaft (shafts);

● With V-shaped engines;

●With engines with 8, 12, 16 and 24 valves;

● With engines with a central location of the candle;

● With engines with lateral spark plugs.

Valve dryer of overhead engines

For the possibility of using the dryer on various engines, a whole set of devices and adapters is provided. For example, adapters for screwing into a spark plug well, screwing in instead of a camshaft cover, screwing into various side holes, etc.

Universal crackers and for overhead engines are also made in the screw version - in such dryers, the lever is replaced by a screw, as in a clamp. The use of a screw allows you to apply significant force to the spring, and most importantly, it fixes the spring in a compressed state for a long time, providing the ability to install new crackers without haste and without errors.

Modern crackers can have various assistive devices. Most often, the universal tool comes with a set of pressure bushings for springs of various diameters, as well as various adapters for screwing into the candle channel and other threaded holes. Professional fixtures may also include adapters or hoses with threaded lugs for connection to a compressor or pneumatic system. This adapter is installed in the candle channel and supplies compressed air to the cylinder - this creates an air pressure that prevents the valve from falling when the spring is compressed. Compressed air is supplied only when drying without dismantling the cylinder head.

Valve dryer of overhead engines

How to choose and use a valve dryer

When selecting a tool, you should take into account the brand of the car and the type of engine with which you have to work.

For professional repair and maintenance of engines, clamping and universal dryers with a set of bushings, threaded supports and other devices are better suited. This tool pays off at a higher cost with its versatility and application capabilities.

The valve dryer should be used in strict accordance with the instructions attached to it and in compliance with basic safety standards. Lever devices are the easiest to use: it is enough to install its support on the cylinder head with a screw, bring the sleeve to the spring plate and press the lever - the spring will shrink and the crackers will be released, after which they can be removed. Universal crackers are used in a similar way, however, depending on the type of engine, they must be installed correctly. For ease of removal of breadcrumbs and safety, you can use a magnet on the rod.

Valve dehumidifier kit in the case

It should be remembered that the valve springs are compressed with great force, so the dryer should be installed securely, and when working with it, do not allow the lever to slip - this can lead to injury. Particular care must be taken when installing breadcrumbs in the case of using a conventional lever device - loosening the lever can lead to injury to the fingers. It is also necessary to monitor the reliability of the installation of the clamping tool, as it can slip off with all the negative consequences.

If the valve dryer is selected correctly and used in compliance with safety regulations, then engine repairs will be performed quickly and without injury.

Post time: Jul-10-2023